With decades of experience in management consulting, Marco Gaietti is a seasoned expert in Business Management, specializing in strategic operations and customer relations. Today, he joins us to discuss the cutting-edge entrance and loading bay systems implemented at Schneider Electric’s new £42 million net-zero manufacturing facility in Scarborough. We’ll explore how these advanced solutions create a seamless, safe, and efficient operational environment, touching on the synergy of integrated loading bay components, the long-term value of innovative springless door technology, the impact of high-speed doors on workflow and thermal efficiency, and the critical strategies behind a multi-layered fire protection system.

The Scarborough facility integrates telescopic dock levellers, shelters, and automatic vehicle restraints. Can you explain how these components work together to ensure safety and efficiency, and what challenges arise when integrating them into a modern, net-zero building design?

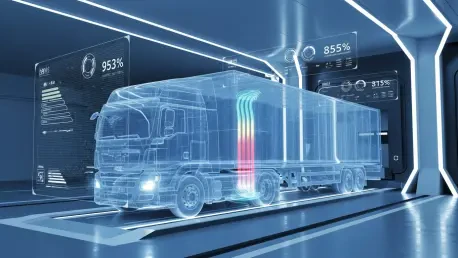

Think of it as a complete, unified system where each part has a critical role in creating a secure and productive environment. When a truck arrives, the dock shelter creates a seal against the building, protecting goods and personnel from the weather, which is crucial for maintaining internal climate control. The telescopic dock leveller then extends to form a perfect bridge between the facility floor and the truck bed, accommodating a wide range of vehicle heights. The final piece, the automatic vehicle restraint, is perhaps the most critical for safety; it physically locks the truck in place, eliminating the terrifying risk of a vehicle creeping away or departing prematurely while a forklift is still inside. The challenge in a net-zero building is that these systems must perform their functions without compromising the building’s highly-tuned thermal envelope. Every seal and connection has to be meticulously planned to prevent energy loss, ensuring the loading bay is an asset to the facility’s sustainability goals, not a detriment.

The Crawford OH114P dock doors feature a springless Dual Drive design aimed at reducing maintenance. Could you walk us through how this technology operates and quantify the potential long-term operational savings and reliability improvements compared to traditional door systems?

The Dual Drive design is a significant leap forward in reliability. Traditional industrial doors rely on massive springs to counterbalance the door’s weight, and these springs are under constant, immense tension. They are the most common point of failure—they fatigue, they snap, and replacing them means significant downtime and maintenance costs. The Crawford OH114P eliminates this weak link entirely. By using a dual-drive motor system, it lifts and lowers the door directly, which results in a much smoother, more controlled, and fundamentally more reliable operation. While the initial investment might be different, the long-term operational savings are substantial. You’re drastically cutting down on emergency repair calls, routine spring replacements, and the associated production stoppages. It’s about shifting from a reactive maintenance model to a more predictable, preventative one, which for a high-volume facility, translates into improved uptime and a healthier bottom line.

With 23 rigid high-speed doors installed, how does their three-second opening speed impact material flow and thermal efficiency across the facility? Please provide an example of how the combination of remote transmitters and radar detection manages both vehicle and pedestrian traffic.

A three-second opening speed is transformative for a facility’s internal logistics. In a busy manufacturing environment, every second counts. When a door opens and closes that quickly, it minimizes the time a forklift or employee has to wait, creating a much smoother, more continuous flow of materials between different zones. This speed is also paramount for thermal efficiency. A slow door is essentially an open window, hemorrhaging heated or cooled air. By reducing the open time to just a few seconds, you dramatically cut down on energy loss, which is absolutely vital in a net-zero facility. For traffic management, the system is both smart and safe. A forklift driver might use a remote transmitter to trigger the door from a distance, ensuring it’s fully open by the time they arrive. Simultaneously, the integrated radar acts as a constant presence detector, holding the door open if a pedestrian unexpectedly walks into the path and preventing it from closing on any vehicle or person. It’s a layered approach that ensures efficiency without ever compromising safety.

Fire protection was a critical element, involving both one-hour and two-hour rated shutters certified to specific standards. What are the key considerations when placing these different systems, and how do audio-visual warning panels contribute to personnel safety during an emergency activation?

The placement of fire shutters is a highly strategic decision dictated by building codes and a thorough risk assessment. The goal is compartmentalization—to contain a fire within a specific area and prevent its spread. You’ll typically see two-hour rated shutters installed to protect critical escape routes, high-risk areas, or walls separating major building sections, giving people more time to evacuate and providing more robust protection for the building’s structure. One-hour shutters might be used for subdividing larger rooms or protecting less critical openings. The audio-visual warning panels are an indispensable safety feature. When a fire alarm is triggered, these panels activate with loud alarms and flashing lights before the shutter begins to close. This pre-deployment warning is designed to stop anyone from moving through the opening, preventing the terrifying scenario of someone being trapped or injured by a descending shutter. It provides those crucial few seconds for people to react and clear the area safely.

What is your forecast for loading bay and industrial door technology?

I foresee a future driven by two main forces: smart integration and sustainability. We’re moving beyond individual components and toward fully integrated, data-driven ecosystems. Loading bays will be equipped with sensors that not only manage safety but also collect data on usage patterns, vehicle wait times, and energy consumption, feeding that information into a building’s management system to optimize logistics in real-time. On the sustainability front, the focus will intensify on materials with higher recycled content, superior insulation properties, and designs that require even less energy to operate. Ultimately, the loading bay of the future won’t just be a door; it will be an intelligent, energy-efficient hub that is fully connected to the facility’s operational and environmental nervous system.