With decades of experience shaping the landscape of modern business management, Marco Gaietti has become a leading voice in strategic operations and supply chain innovation. We’re sitting down with him to discuss a significant leap forward in logistics: the recent launch of a cutting-edge automated storage and retrieval system at a major Dutch distribution center. This new system promises not just to solve pressing labor shortages but to redefine efficiency and scalability for the fast-paced world of fashion and lifestyle brands.

The AutoStore system reportedly uses up to seven times less space than traditional racking. Could you detail how this high-density storage is physically achieved and explain how it improves your ability to manage inventory for multiple clients simultaneously? Please provide a tangible example of this efficiency.

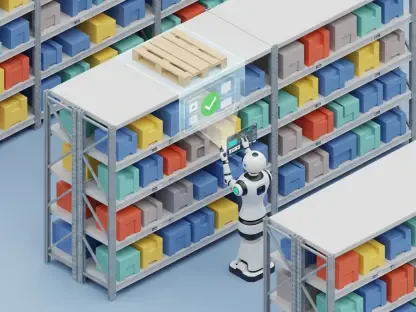

It’s truly a game-changer in warehouse design. Instead of long aisles of racking that require significant floor space for people and machines to navigate, the system uses a dense, grid-like structure. Inventory is stored in bins stacked directly on top of one another. Radio-controlled robots travel across the top of this grid, digging down to retrieve the specific bin required. This complete elimination of wasted aisle space is how we achieve that incredible footprint reduction, sometimes up to seven times less than a traditional layout. For our operations, this means we can bring multiple clients’ entire inventories into a single, compact system. This co-storage dramatically increases our capacity, allowing us to hold a wider variety of SKUs and significantly reduce the risk of stock shortages for everyone under our roof.

You’ve integrated an automated storage solution with a conveyor and packing system to speed up fulfillment. Can you walk me through the step-by-step journey of an item from the moment it’s retrieved by a robot to when it leaves in a sealed carton for delivery?

Absolutely. The process is designed for maximum speed and minimal handling. Once an order is received, a robot is dispatched across the grid to locate and retrieve the correct bin containing the item. This bin is then transported directly to a goods-to-person picking station. It’s at this very moment that the product is touched for the first and only time by a human operator, who picks the item and places it onto an advanced conveyor system. From there, it’s a fully automated journey. The item travels to an autonomous packing station where a carton is erected, the item is placed inside, and the machine even reduces the height of the carton to minimize shipping volume before sealing it for dispatch. It’s a seamless flow from storage to a ready-to-ship package.

It’s claimed that a product is touched by only a single pair of hands throughout the entire process. How does minimizing human manipulation in this way specifically reduce errors and boost productivity? Could you share an anecdote or metric illustrating this improvement?

That “single touch” principle is the cornerstone of the system’s accuracy and efficiency. In a traditional warehouse, an item might be handled five or six times—during put-away, replenishment, picking, sorting, and packing. Each touchpoint is a potential opportunity for a mistake, whether it’s misplacing an item, picking the wrong one, or a packing error. By consolidating this down to a single, focused interaction where the system presents the correct item directly to the operator, we virtually eliminate those chances for error. The productivity gains are immense because we’ve cut out all the non-value-added travel time. Our staff are no longer walking miles of aisles; they’re focused on the one task that requires their dexterity and judgment, leading to a much faster and more reliable fulfillment cycle.

As automation is implemented to address labor scarcity, how have the day-to-day roles and skill sets of your warehouse staff evolved? What new training or career development opportunities has this technology introduced for your team at the Almelo facility?

This is one of the most exciting transformations we’re seeing. Instead of focusing on physically demanding and repetitive tasks like walking and heavy lifting, our team members are evolving into system operators and technicians. Their roles are now more focused on overseeing the automated workflow, managing inventory within the system, and ensuring the technology runs smoothly. We are investing heavily in training them on the new software interfaces and the mechanics of the system. This creates a clear career path from a traditional warehouse associate to a highly skilled logistics technician, which is not only more engaging for the employee but also more valuable for the business in the long run.

The system can intelligently make popular items more accessible and be programmed for peak sales. Could you explain how it anticipates demand to reorganize inventory and what the process of preparing for a major sales event like Black Friday looks like from an operational standpoint?

The intelligence of the system is remarkable. During normal operations, it learns which items are frequently requested and automatically shuffles those bins to the top of the grid, making them quicker to retrieve. It’s a self-optimizing process that happens constantly. When we’re preparing for a massive peak like Black Friday, we take a more proactive approach. We can program the system with our sales forecasts, telling it which specific items we expect to be top-sellers. The robots will then work during off-hours to strategically reposition those products to the most accessible locations. This means that when the surge of orders hits, we’ve already done the prep work, saving valuable time and ensuring we can meet those incredibly demanding delivery promises.

Scalability seems to be a major advantage. If a client suddenly requires extra capacity for a sales spike, could you describe the practical steps involved in expanding the system’s capabilities without disrupting ongoing operations? Please elaborate on how you maintain service levels during such a transition.

The modular design is the key to its exceptional flexibility. Expansion is remarkably straightforward and, most importantly, non-disruptive. If we need to increase throughput, we can simply add more robots to the grid; they can be commissioned and set to work almost immediately. If we need more storage capacity, we can extend the grid structure itself. This construction can be done section by section while the rest of the system continues to operate at full capacity. This means we can react to a client’s growth or a seasonal peak like the holidays by scaling up our capabilities on the fly, all without ever having to shut down or compromise our service levels.

The energy efficiency of the robots allows for “lights-out” logistics. Beyond the obvious savings on electricity, what are some of the other operational or sustainability benefits you have observed from being able to run the system with minimal lighting and low power consumption?

The energy savings are indeed significant—ten robots use about the same power as a single vacuum cleaner, which is astounding. Running “lights-out” is a huge part of that. Beyond the direct electricity cost savings, this creates a more sustainable and efficient operation overall. It reduces our facility’s carbon footprint, which is a major goal for us and our clients. Operationally, it simplifies the environment. We don’t have to worry about lighting maintenance or climate control in the same way you would for a human-centric workspace. This low-energy, low-infrastructure environment contributes to a more resilient and cost-effective operation, allowing us to pass those efficiencies on to our partners.

What is your forecast for automation in fashion and lifestyle logistics?

I believe we’re just at the beginning of a massive wave. The pressures of labor scarcity, rising consumer expectations for next-day delivery, and the need for operational resilience are not going away. My forecast is that highly scalable, high-density automated systems like this will become the industry standard, not the exception. We will see even tighter integration with AI for predictive analytics and more sophisticated robotics for tasks beyond picking. The future of fashion logistics is one where human talent is elevated to oversee intelligent, autonomous systems that are not only incredibly efficient and accurate but also more sustainable and adaptable to the volatile demands of the modern market.