In today’s fast-paced technological landscape, the importance of accurate forecasting in supply chain and warehousing management cannot be overstated. Forecasting, defined as predicting future demand, is critical for optimizing inventory levels, efficiently managing resources, and making informed strategic decisions. This process involves a blend of qualitative and quantitative methods, significantly enhanced by advanced technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT).

Differentiating Forecasting Techniques

Qualitative and quantitative forecasting techniques each play pivotal roles in supply chain management. Qualitative methods, like the Delphi Method and market research, are invaluable when historical data is either sparse or unreliable. These techniques rely heavily on expert opinions and consumer insights, making them particularly useful in uncertain conditions. On the other hand, quantitative methods such as time series analysis, exponential smoothing, and machine learning algorithms utilize historical data and mathematical models to deliver precise forecasts. Together, these techniques ensure that supply chains can adapt to both short-term and long-term demands effectively.

Enhancing Forecasting with Advanced Tools and Technologies

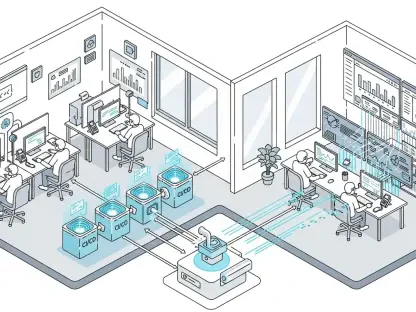

Implementing sophisticated tools and technologies significantly boosts forecasting capabilities. AI, for instance, automates planning processes, improves decision-making, and predicts consumer behavior with remarkable accuracy. Meanwhile, IoT devices provide real-time data on inventory and equipment status, optimizing warehouse operations. Integrating electronic data interchange (EDI) and enterprise resource planning (ERP) systems has also revolutionized data management and analysis, thereby enhancing the efficiency and operational coherence of supply chains.

Challenges in Effective Forecasting

Despite its benefits, effective forecasting faces several challenges. Issues like data accuracy and the ability to adapt to unforeseen market changes pose significant hurdles. Additionally, the resource-intensive nature of adopting new technologies can be a barrier for many companies. Robust data management strategies and continuous refinement of forecasting models are essential to overcome these challenges and achieve substantial accuracy in predictions.

Emerging Trends in Forecasting

Several emerging trends are shaping the future of demand forecasting in supply chain and warehousing management. Real-time data processing enabled by edge computing significantly enhances the timeliness and accuracy of forecasts. The increasing integration of IoT devices into supply chains is also noteworthy, as these devices greatly aid in inventory management and overall efficiency. Furthermore, combining IoT data with advanced predictive analytics offers deep insights into patterns and anomalies. The adoption of AI solutions continues to grow, with many companies reporting positive impacts on their supply chain functions.

Key Metrics for Effective Forecasting

Certain key metrics and indicators are fundamental for effective forecasting. These include customer demand prediction, inventory level management, forecast accuracy, lead times, seasonality trends, data quality, supply chain visibility, and cost management. By meticulously monitoring these metrics, companies can enhance their supply chain responsiveness, operational efficiency, and customer satisfaction.

Applications in Supply Chain and Warehousing Management

Forecasting in supply chain management has several critical applications, including demand forecasting, internal demand planning, and inventory optimization. Accurate forecasts help minimize waste, improve sustainability, and optimize logistics and transportation planning. In warehousing management, precise forecasts reduce storage fees, optimize space utilization, and manage perishable goods more effectively.

Case Studies and Real-World Implications

Various case studies highlight the transformative impact of forecasting. For instance, applying big data analytics in supply chain management significantly enhances predictive accuracy and operational efficiency. Educational programs and leadership training also underscore the importance of mastering forecasting skills, extending their relevance beyond operational planning to strategic organizational development.

Conclusion

In today’s rapidly evolving technological environment, the significance of precise forecasting in supply chain and warehousing management is immense. Forecasting, the practice of estimating future demand, plays a crucial role in streamlining inventory levels, managing resources effectively, and making strategic, evidence-based decisions. The forecasting process is a combination of both qualitative and quantitative approaches, greatly enhanced by modern technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These advancements enable real-time data analysis, offering deeper insights and more accurate predictions. For example, AI can identify patterns and trends that humans might overlook, while IoT devices provide up-to-the-minute information on stock levels and supply chain conditions. Machine learning algorithms refine forecasts by continuously learning from new data. The integration of these technologies not only improves accuracy but also enhances the agility and responsiveness of supply chain operations. In such a dynamic landscape, businesses that leverage advanced forecasting tools can stay ahead of the curve, ensuring they meet customer demand efficiently while minimizing costs and avoiding overstock or stockouts.