I’m thrilled to sit down with Marco Gaietti, a veteran in business management with decades of experience in strategic operations and customer relations. Marco has a deep understanding of how logistics and storage solutions can make or break manufacturing efficiency. Today, we’re diving into the world of high-density storage systems, exploring how they keep production lines humming, the critical factors in choosing the right setup, and the innovative options available for manufacturers looking to optimize space and speed.

How would you define high-density storage in the manufacturing world, and why is it such a game-changer for maintaining smooth production flows?

High-density storage, in essence, is about maximizing the use of available space in a warehouse or factory to store more goods in a smaller footprint. For manufacturers, it’s a game-changer because it allows parts, raw materials, and semi-finished products to be kept close to production lines. This proximity cuts down on retrieval times, which is critical for Just-In-Time supply systems. Without efficient storage, you risk delays or even halts in production, and that’s a costly problem no manufacturer can afford.

What key elements should manufacturers weigh when figuring out the best storage density for their facilities?

There are several factors at play here. First, you’ve got to look at your stock profile—what kinds of items you’re storing, their turnover rates, and their physical characteristics. Then, there’s the upfront investment in racking systems; you need to balance cost with long-term benefits. Handling and transport costs per item are also huge, as they include labor and internal movement expenses. Finally, picking capacity, or how many items you can retrieve in a given time, directly affects how your storage system should be designed. It’s about finding harmony between space, cost, and speed.

Let’s dive into drive-in racking. In what scenarios does this system shine for manufacturers?

Drive-in racking is fantastic for manufacturers dealing with large volumes of identical items or goods that don’t need to be picked in a specific order. It’s also ideal for pressure-sensitive or unstable loads since it minimizes handling. The system uses a Last In, First Out—or LIFO—approach, which works well when stock rotation isn’t a priority, allowing you to pack a lot into a tight space.

Moving on to mobile pallet or cantilever racking, how does this setup help optimize space in a manufacturing environment?

Mobile racking is a real space-saver. It can boost storage capacity by up to 200% on the same footprint or cut floor space needs by half. The racks move to create a single aisle where needed, so you’re not wasting space on permanent walkways. It’s a clever way to make the most of limited factory real estate, especially when space is prioritized for production over storage.

For operations with frequent picking, how do pallet and carton live systems balance dense storage with quick access to products?

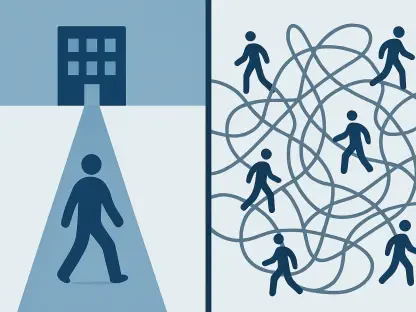

Pallet and carton live systems are designed for both density and accessibility. They use flow lanes where items are loaded from the back and roll forward to the pick face on rollers, so every product line is right there for the taking. This setup holds enough stock to ensure constant availability while keeping the footprint small. Plus, with separate loading and picking aisles, you get a safer, more efficient workflow by keeping lift trucks and pedestrian pickers apart.

You’ve mentioned mechanical solutions like live systems as a middle ground for fast-moving parts. What makes them such a practical choice in terms of investment and performance?

Mechanical solutions like live systems strike a sweet spot between cost, storage density, and retrieval speed. They don’t require the heavy investment of full automation but still deliver compact storage and quick access for fast-moving parts. They’re adaptable too—adding tech like pick-to-light or voice picking can ramp up accuracy and throughput without breaking the bank, making them a versatile option for many manufacturers.

High-rise narrow aisle racking seems like an innovative way to use vertical space. Can you walk us through how this system maximizes capacity and what challenges might come with it?

High-rise narrow aisle racking is all about going up instead of out. With aisle widths as tight as 1.6 to 2 meters and heights up to 15 meters—or even over 30 in automated high-bay setups—it offers incredible density. It’s typically serviced by man-operated stacker cranes or very narrow aisle trucks, which keep operations precise with guide rails or inductive steering. The challenge, though, is that taller setups often need wider aisles for broader equipment, and the initial setup cost can be steep. Plus, you need skilled operators to handle the heights safely.

What’s your forecast for the future of high-density storage solutions in manufacturing?

I see high-density storage becoming even more integrated with automation and smart technology. As manufacturers push for faster, leaner operations, we’ll likely see more hybrid systems that blend mechanical setups with advanced tools like AI-driven inventory management and robotic picking. Space will always be at a premium, so vertical solutions and modular designs will continue to evolve, offering flexibility for changing production needs. It’s an exciting time for innovation in this field, and I think we’re just scratching the surface of what’s possible.