In the fast-paced world of manufacturing, maintaining high-quality production lines is a critical challenge that can make or break a business’s reputation and profitability, and every manufacturer strives to deliver flawless products while keeping costs under control. Achieving this balance often seems like an uphill battle, but the good news is that significant improvements in quality don’t always require massive investments or complete overhauls of existing systems. By implementing smart, efficient strategies, it’s possible to enhance production line quality without straining budgets. This article explores six practical shortcuts that can elevate the standards of manufacturing processes. These methods focus on identifying issues, fostering a proactive culture, and leveraging simple tools to prevent errors. Each approach is designed to be actionable and cost-effective, ensuring that businesses of all sizes can adopt them to achieve better results on the production floor.

1. Conduct Regular Defect Autopsies

Identifying and addressing defects is a fundamental step in improving production line quality, and conducting regular defect autopsies offers a structured way to achieve this. These sessions don’t need to be lengthy; dedicating just 30 to 60 minutes weekly can yield significant insights. During these autopsies, operators and supervisors can analyze defective items to pinpoint where processes are failing. This practice helps uncover recurring issues, whether they stem from equipment malfunctions, material inconsistencies, or human error. By systematically dissecting each problem, teams can develop targeted solutions that prevent future defects. The key is to approach these sessions with a problem-solving mindset, ensuring that every finding translates into a concrete action plan. This shortcut not only improves product quality but also fosters a culture of continuous improvement among staff, as they become more attuned to potential weaknesses in the production process.

Beyond identifying issues, defect autopsies serve as a valuable learning tool for refining operational efficiency on the production line. Once the root causes of defects are understood, manufacturers can implement specific adjustments, such as recalibrating machinery or retraining employees on critical tasks. This proactive approach minimizes downtime and reduces the likelihood of defective products reaching customers. Additionally, documenting findings from each session creates a historical record that can be referenced to track progress over time. This data-driven method ensures that solutions are not just temporary fixes but part of a long-term strategy to elevate quality standards. By making defect autopsies a regular practice, businesses can stay ahead of potential problems, ensuring that their production lines consistently deliver high-quality outputs without the need for costly interventions or extensive redesigns.

2. Encourage a Stop-The-Line Culture

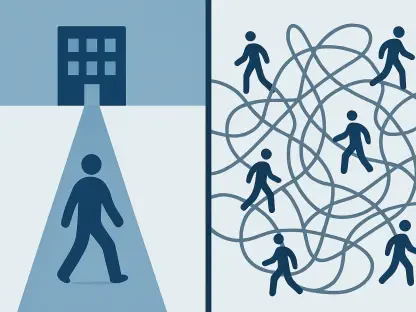

Fostering a culture where employees feel empowered to stop the production line when they notice a defect is a powerful way to maintain quality. While halting operations may seem counterintuitive due to the immediate cost of downtime, it ultimately prevents larger issues down the line. Many modern production setups are equipped with emergency shut-off mechanisms that regular staff are authorized to activate. When a problem is detected, stopping the line allows for immediate correction, ensuring that defective products don’t progress further. Rewarding employees for taking such actions reinforces the importance of quality over quantity. This approach not only curbs the spread of defects but also builds trust among team members, as they see their vigilance directly contributing to better outcomes on the production floor.

Implementing a stop-the-line culture requires clear communication and support from management to ensure employees understand the value of their actions. Training programs can help staff recognize critical defects and feel confident in making the call to pause operations. Additionally, establishing a reward system—whether through recognition or small incentives—can motivate workers to prioritize quality without fear of repercussions for slowing production. Over time, this practice leads to fewer defective products reaching the end of the line, reducing waste and enhancing customer satisfaction. The financial impact of brief stoppages pales in comparison to the cost of recalls or reputational damage caused by substandard goods. By embedding this mindset into daily operations, manufacturers can create a proactive environment where quality is everyone’s responsibility, leading to sustained improvements across the board.

3. Utilize Quarantine Bins for Analysis

Another effective shortcut to boost production line quality is the use of quarantine bins for isolating questionable parts or products. These designated containers allow manufacturers to segregate defective items as soon as they are identified, preventing them from mixing with acceptable inventory. Once isolated, these parts can be thoroughly analyzed to determine what went wrong during the production process. This method provides a clear starting point for tracing issues back to their source, whether it’s a faulty component, an operator error, or a machine malfunction. Quarantine bins serve as both a physical and procedural safeguard, ensuring that defective items are addressed before they impact the broader production cycle or reach customers.

The real value of quarantine bins lies in their ability to create a documented history of defects, which can be used to identify patterns and implement lasting solutions. By maintaining a log of quarantined items, manufacturers can track recurring problems and prioritize fixes that address the most frequent or severe issues. This analytical approach transforms isolated incidents into opportunities for systemic improvement. Furthermore, the presence of quarantine bins sends a message to employees about the importance of quality control, encouraging them to be vigilant in spotting defects. Implementing this system requires minimal investment, yet it delivers substantial returns by reducing the risk of defective products slipping through. Over time, this practice can significantly enhance the reliability and consistency of production outputs.

4. Invest in High-Quality Finishing Systems

Enhancing the final appearance of products through high-quality finishing systems is a shortcut that directly impacts perceptions of quality. Industrial pneumatic solutions and advanced spray systems can give products a polished, professional look that appeals to both business clients and end consumers. While the initial setup of these systems requires careful planning and investment, the long-term benefits are substantial. Properly finished products not only meet aesthetic standards but also often indicate a higher level of care in the manufacturing process. This attention to detail can differentiate a brand in competitive markets, where visual appeal often influences purchasing decisions.

Beyond aesthetics, high-quality finishing systems contribute to durability and functionality, further elevating product standards. These systems ensure consistent application of coatings or treatments, reducing variability that could lead to defects. Manufacturers should focus on selecting equipment that aligns with their specific production needs and provides reliable performance over time. Regular maintenance of these systems is also crucial to avoid disruptions or subpar results. By integrating advanced finishing solutions into the production line, businesses can achieve a noticeable improvement in quality without overhauling other processes. This targeted upgrade often results in positive feedback from customers, reinforcing the value of investing in the final stages of production for maximum impact.

5. Implement Daily Quality Huddles

Daily quality huddles, lasting just 15 minutes, offer a quick and effective way to keep production line quality in check. These brief meetings bring together team members to review the current state of operations and discuss any issues noticed on the line. Commonly used in retail, this practice translates well to manufacturing by providing a platform for immediate communication. During huddles, staff can highlight problems that might otherwise go unnoticed until they escalate, enabling swift corrective actions. This regular check-in ensures that quality remains a daily priority, rather than an afterthought addressed only after defects are discovered.

The strength of quality huddles lies in their ability to foster collaboration and transparency among production teams. These sessions create an environment where employees feel comfortable sharing observations and suggestions, often revealing insights that management might miss. To maximize effectiveness, huddles should focus on actionable outcomes, such as assigning tasks to address specific issues raised. Over time, this routine builds a shared commitment to maintaining high standards, as every team member becomes an active participant in quality control. By embedding daily huddles into the workflow, manufacturers can tackle minor issues before they become major setbacks, ensuring smoother operations and consistently better products.

6. Adopt Error-Proofing Devices

Finally, incorporating error-proofing devices into production lines serves as a critical shortcut for preventing defects from occurring in the first place. Tools such as limit switches, which halt operations if a part is missing, or go/no-go gauges, which verify component specifications, can significantly reduce errors. These devices act as automated safeguards, catching mistakes before they progress through the production cycle. Depending on the specific needs of the manufacturing process, different error-proofing solutions can be tailored to address unique challenges, ensuring that quality is maintained at every stage.

The implementation of error-proofing devices not only minimizes defects but also boosts overall efficiency by reducing the need for manual inspections. These tools provide immediate feedback, allowing operators to correct issues on the spot without extensive downtime. Investing in such technology demonstrates a commitment to precision and reliability, which can enhance customer trust in the final product. Manufacturers should evaluate their production lines to identify areas most prone to errors and prioritize error-proofing solutions accordingly. By integrating these devices, businesses can achieve a higher level of consistency, ensuring that quality standards are upheld with minimal human intervention.

Final Steps to Quality Excellence

Reflecting on the strategies discussed, it becomes clear that small, deliberate actions often yield the most significant improvements in production line quality. Each shortcut, from conducting defect autopsies to adopting error-proofing devices, proves to be a practical step toward perfection without overwhelming budgets. Moving forward, manufacturers are encouraged to start with one or two of these methods, tailoring them to their specific needs and scaling up as results emerge. Prioritizing staff training alongside these initiatives ensures lasting impact, as empowered teams play a pivotal role in sustaining high standards. Additionally, regularly reviewing the effectiveness of implemented changes helps refine approaches over time. By taking these actionable next steps, businesses position themselves to not only meet but exceed customer expectations, securing a competitive edge in the ever-evolving manufacturing landscape.