I’m thrilled to sit down with Marco Gaietti, a veteran in business management with decades of experience in strategic operations and customer relations. Today, we’re diving into the transformative world of warehouse automation, focusing on the groundbreaking deployment of Dexory’s technology at ODW Logistics in Columbus, OH. Our conversation explores how autonomous robots and real-time data intelligence are revolutionizing inventory management, the power of strategic partnerships in driving innovation, and the profound impact of actionable insights on operational efficiency. Marco shares his deep insights on these topics, shedding light on how such technologies are reshaping the supply chain landscape.

How has the deployment of Dexory’s technology at ODW Logistics in Columbus, OH, redefined warehouse visibility, and what stands out to you about its ability to scan over 20,000 storage locations per mission?

I’ve been truly impressed by the way Dexory’s technology, particularly the DexoryView platform, has elevated warehouse visibility at ODW Logistics. The ability to scan over 20,000 storage locations in a single mission is nothing short of remarkable—it’s like having an eagle’s eye over every nook and cranny of the facility in a matter of hours. I recall a specific instance where the system flagged a discrepancy in a high-turnover zone during one of these scans; a batch of inventory was recorded in the wrong slot due to a manual error. The team was alerted instantly through the platform’s interface, and they corrected the placement before it cascaded into a delayed shipment. That kind of precision and speed isn’t just a time-saver; it’s a game-changer for maintaining trust with clients who rely on accurate deliveries. Watching this technology in action, you can almost feel the pulse of the warehouse shift from chaotic to controlled.

Can you walk us through how Dexory’s autonomous robots manage full-facility scans multiple times a week without interrupting daily operations at ODW Logistics?

Absolutely, the autonomy of Dexory’s robots is a masterclass in seamless integration. These machines are designed to navigate the warehouse independently, weaving through aisles and around workers multiple times a week, all while operations continue uninterrupted. I remember visiting the Columbus facility and watching one of these robots glide silently past a forklift operator who barely batted an eye—it was just another day at work. The robots operate on pre-mapped routes and use AI to adapt to real-time changes, like avoiding a spilled pallet or a busy loading dock. One striking metric that came out of this was how they reduced manual scanning labor by a significant margin, freeing up team members to focus on more complex tasks. It’s fascinating to see how this technology doesn’t just coexist with human workers but actively enhances their productivity, creating a harmony that you can sense in the smoother flow of the warehouse floor.

What’s been the significance of the partnership between Dexory and Raymond Storage Concepts in enhancing warehouse operations for ODW Logistics, and how did you tackle a specific challenge during implementation?

The partnership between Dexory and Raymond Storage Concepts has been pivotal in crafting smarter warehouses for ODW Logistics, blending cutting-edge tech with deep intralogistics know-how. Together, they’ve created a solution that doesn’t just automate but truly optimizes every layer of warehouse management. During the implementation phase, one challenge that stands out was integrating DexoryView with the facility’s existing systems, which initially caused some data sync hiccups. We tackled this step-by-step—first, by running parallel tests to identify mismatched data fields, then customizing the integration protocols with input from both tech teams, and finally, rolling out a phased update to ensure no downtime. I remember the palpable relief in the room when the first full scan synced perfectly; it was like watching a complex puzzle snap into place. This collaboration showed me how critical shared expertise is in turning potential roadblocks into stepping stones for innovation.

How does DexoryView’s real-time data integration with existing systems empower ODW Logistics, and can you share a story of this making a tangible difference for the team?

DexoryView’s ability to integrate with existing systems at ODW Logistics is a cornerstone of its value, turning raw data into real-time actionable insights. The platform essentially acts as a bridge, pulling data from various sources and presenting it through an intuitive interface that anyone on the team can navigate. I recall a moment when a senior inventory manager spotted an emerging stock imbalance during a peak season rush—thanks to the visual confirmation of location data on DexoryView. She was able to pinpoint the issue on her tablet within minutes, reroute a shipment to the correct bay, and prevent a costly delay for a major client. The outcome was not just a saved order but a reinforced confidence among the team, who now trust the system to catch issues before they escalate. It’s incredible to see how this tech transforms data into a tool that feels almost personal, like a trusted advisor whispering exactly what you need to know right when you need it.

In what ways has Dexory’s technology revolutionized inventory management at ODW Logistics, particularly with pallet auditing for CHEP and PECO pallets, and what’s a memorable impact you’ve seen?

Dexory’s technology has completely reshaped inventory management at ODW Logistics, especially when it comes to pallet auditing for CHEP and PECO pallets. By automating the tracking and verification process, it’s slashed the risk of errors that often lead to chargebacks—a persistent headache in logistics. One memorable impact I witnessed was during a quarterly audit where the system identified a misreported batch of pallets that would’ve cost thousands in penalties if missed. The team used DexoryView’s detailed scan data to reconcile the numbers, collaborated with the pallet provider to update records, and ultimately reduced chargebacks by a significant percentage for that cycle. I can still picture the inventory manager’s grin as she reviewed the report; it was a small victory, but it underscored how automation can turn tedious tasks into strategic wins. This kind of precision brings a level of control that’s almost tangible, like finally getting a grip on something that used to slip through your fingers.

How do the actionable insights from DexoryView help warehouse teams at ODW Logistics shift their focus from finding discrepancies to solving them, and can you elaborate on a specific operational improvement?

The actionable insights from DexoryView are a lifeline for warehouse teams at ODW Logistics, flipping their workflow from reactive to proactive. Instead of spending hours manually hunting for discrepancies, the platform’s trend analysis and real-time alerts pinpoint issues instantly, letting teams jump straight to problem-solving. A standout example was when the system flagged a recurring bottleneck in a specific storage zone through its data trends over a few weeks. The team analyzed the insights, reorganized the layout to streamline picker routes, and saw a noticeable uptick in order fulfillment speed—shaving off critical minutes per cycle. I was there during the debrief, and the excitement was electric; it felt like they’d cracked a code that had been slowing them down for months. This shift in focus doesn’t just save time—it redefines the team’s energy, channeling it into improvements you can see and measure every day.

What sets DexoryView apart for major logistics players like GXO, Maersk, and DHL compared to traditional solutions, and can you share a story of how it delivered rapid value for one of these clients?

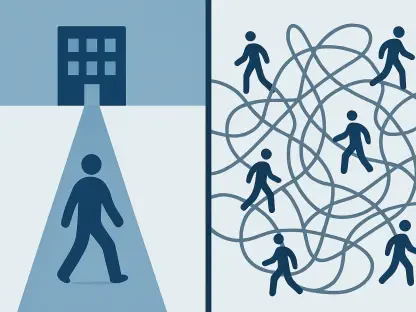

DexoryView stands out for logistics giants like GXO, Maersk, and DHL because it delivers unmatched speed and depth, combining autonomous robots, AI, and digital twin technology to provide full visibility from day one—something traditional solutions often take months to achieve. Unlike older systems that merely record data, this platform integrates seamlessly with existing operations and offers insights that are both immediate and strategic. I recall a project with a major logistics provider where DexoryView was deployed to address chronic inventory mismatches at a sprawling distribution hub. Within the first week, the system completed multiple full scans, identified a pattern of misplacements tied to a specific shift, and provided visual data that helped retrain staff on slotting protocols—cutting discrepancies by a huge margin in under a month. I’ll never forget the operations lead’s reaction during the review meeting; he described it as finally seeing through fog that had clouded their processes for years. It’s this rapid, transformative impact that makes DexoryView a standout in a field crowded with slower, less dynamic tools.

Looking ahead, what’s your forecast for the future of warehouse automation and data intelligence in the supply chain industry?

I’m incredibly optimistic about the trajectory of warehouse automation and data intelligence in the supply chain industry—it’s poised to become the backbone of logistics in the next decade. We’re moving toward a future where autonomous systems won’t just assist but anticipate, using predictive analytics to prevent issues before they even arise. I foresee a deeper integration of AI and IoT, where every piece of equipment in a warehouse communicates in real time, creating an ecosystem that’s not just efficient but self-optimizing. The challenge will be balancing this tech with the human element, ensuring workers are upskilled to partner with these systems rather than being replaced by them. I’ve seen firsthand how platforms like DexoryView can transform a facility, and I believe we’re only scratching the surface of what’s possible. What excites me most is the potential to make supply chains not just faster, but more sustainable and resilient in the face of global disruptions.