In an era where consumer expectations are soaring and product complexity is at an all-time high, Artificial Intelligence (AI) is emerging as a transformative force in quality control across various industries. From the bustling floors of manufacturing plants to the precise assembly lines of automotive giants, AI is stepping in to address the limitations of traditional human inspection methods with unparalleled accuracy and efficiency. This technology is no longer just a futuristic concept but a practical solution that companies are adopting to ensure their products meet stringent standards while maintaining a competitive edge in crowded markets. The integration of AI into quality assurance processes is not merely about catching defects; it represents a fundamental shift in how industries operate, promising cost savings, faster production cycles, and a future where errors are virtually eliminated. This exploration delves into the profound ways AI is reshaping quality control, highlighting its benefits, challenges, and the exciting possibilities that lie ahead.

Unleashing Unmatched Accuracy and Speed

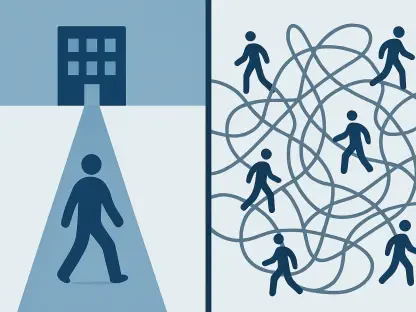

AI’s capacity to process enormous volumes of data at lightning speed is redefining the benchmarks for quality inspections in industrial settings. Unlike human inspectors, who may overlook minute defects due to fatigue or inherent limitations, AI-driven systems employ advanced algorithms and visual inspection tools to detect flaws with pinpoint precision. These systems analyze patterns and anomalies in real time, ensuring that even the smallest inconsistencies are flagged before they become larger issues. This heightened accuracy translates to fewer defective products reaching the market, significantly reducing the risk of costly recalls and protecting brand reputation. Industries that rely on high standards, such as electronics and pharmaceuticals, are particularly benefiting from this technology, as it guarantees that every item meets rigorous quality criteria without exception.

Beyond precision, AI is dramatically enhancing the speed of quality control processes, allowing industries to keep pace with growing demand. These systems operate continuously, unaffected by the need for breaks or shift changes, which minimizes downtime and maximizes throughput on production lines. By automating repetitive and time-consuming tasks, AI enables faster inspections without compromising on thoroughness, ensuring that large batches are processed efficiently. This relentless efficiency not only boosts productivity but also allows businesses to scale operations seamlessly during peak periods. As a result, companies can meet tight deadlines and customer expectations while maintaining consistency, a critical factor in today’s fast-moving markets where delays can mean lost opportunities.

Driving Cost Savings and Operational Gains

One of the most compelling advantages of AI in quality control is its ability to deliver substantial cost savings through streamlined operations. By automating routine inspection tasks, AI reduces the reliance on manual labor, cutting down on associated expenses such as wages and training. Additionally, the precision of AI systems minimizes material waste by catching defects early in the production cycle, preventing the need for rework or scrapping of faulty items. These savings can be redirected toward innovation, research, or expansion, providing companies with a financial edge in competitive sectors. Manufacturing and automotive industries, for instance, are leveraging AI to optimize resource use while ensuring that every product adheres to strict safety and performance standards.

AI’s impact on operational efficiency extends beyond mere cost reduction, reshaping how human resources are allocated within industries. With mundane quality checks handled by intelligent systems, skilled workers are freed up to focus on more strategic roles that require critical thinking and creativity, such as process improvement or product design. This shift not only enhances workforce productivity but also fosters a more innovative workplace environment where human expertise is utilized to its fullest potential. Furthermore, the consistency of AI-driven inspections ensures uniform quality across high-volume production runs, reducing variability that can frustrate customers. As industries continue to adopt this technology, the ripple effect of operational gains is evident in shorter lead times and stronger market positioning.

Overcoming Barriers to AI Integration

Despite its transformative potential, integrating AI into quality control systems presents significant challenges that industries must navigate carefully. The initial investment required for AI technology, including hardware, software, and system integration, can be daunting, especially for small and medium-sized enterprises with limited budgets. This financial barrier often deters adoption, as the upfront costs may outweigh short-term gains, creating hesitation among decision-makers. However, strategies such as phased implementation, where AI tools are introduced gradually, can help mitigate this burden by spreading expenses over time and allowing businesses to scale adoption based on measurable returns. Addressing this challenge requires a long-term perspective on the value AI brings to quality assurance.

Another hurdle lies in ensuring compatibility between cutting-edge AI systems and existing industrial infrastructure, which may be outdated or rigid. Many companies operate with legacy equipment that wasn’t designed to interface with modern technologies, leading to potential disruptions during integration. A thorough assessment of current systems is essential to identify gaps and plan necessary upgrades before deployment, avoiding costly downtime or inefficiencies. Equally important is the need to train staff to effectively manage and interpret AI outputs, as the technology’s benefits are only realized when users are equipped with the right skills. Comprehensive training programs and ongoing support can bridge this gap, ensuring a smoother transition and maximizing the return on investment in AI for quality control.

Envisioning a Smarter Future for Quality Assurance

As AI continues to evolve, its role in quality control is poised to expand with groundbreaking advancements that promise even greater impact. Edge computing, for instance, is emerging as a game-changer by enabling real-time data processing directly at the production site, eliminating delays associated with cloud-based analysis. This capability allows for instantaneous defect detection and corrective action, enhancing responsiveness in fast-paced environments. When combined with the Internet of Things (IoT), AI can access a network of connected devices to monitor equipment health and product quality continuously, creating a proactive rather than reactive approach to quality assurance. Such innovations are setting the stage for unprecedented standards in industries worldwide.

Looking further ahead, the convergence of AI with other emerging technologies hints at a future where quality control becomes entirely predictive and preemptive. Smart systems could anticipate defects before they occur by analyzing historical data and real-time inputs, allowing companies to address issues at the design or early production stages. This forward-thinking approach not only saves resources but also builds consumer trust through consistently superior products. Industries adopting these trends are likely to lead the charge in digital transformation, redefining what excellence means in a competitive global market. The potential for AI to integrate seamlessly with broader industrial ecosystems underscores its role as a cornerstone of future quality assurance strategies, pushing boundaries beyond current imagination.

Reflecting on AI’s Transformative Journey

Looking back, the adoption of AI in quality control marked a pivotal moment for industries striving to balance efficiency with excellence. It tackled longstanding issues of human error and operational bottlenecks, delivering solutions that enhanced precision and slashed costs across sectors like manufacturing and automotive. Challenges such as high initial investments and integration complexities were met with innovative approaches like phased rollouts and targeted training, proving that barriers could be overcome with strategic planning. The journey also saw the emergence of trends like edge computing and IoT, which amplified AI’s impact by enabling real-time, data-driven decisions. As this chapter unfolded, it became clear that AI had not only reshaped quality assurance but also set a foundation for future advancements. Moving forward, industries should focus on fostering collaboration between technology providers and internal teams to ensure seamless adoption, while investing in continuous learning to keep pace with evolving tools and standards.