With decades of experience navigating the complexities of business management and operations, Marco Gaietti has a unique perspective on the transformative power of strategic automation. He joins us to dissect the recent collaboration between FORTNA and RAM Hand-to-Hand Couriers, a project set to redefine parcel logistics in South Africa. We will explore how this new automated facility masterfully balances the roles of a national hub and a local depot, the nuances of tailoring global technology to specific market challenges, and the forward-thinking strategies embedded in its design to ensure long-term scalability and an elevated customer experience.

The new Isando facility is engineered to perform a dual role as both a central hub and a last-mile depot. Could you walk us through how the automation choices enable it to balance these two distinct functions, and how a single parcel’s journey might change depending on its ultimate destination?

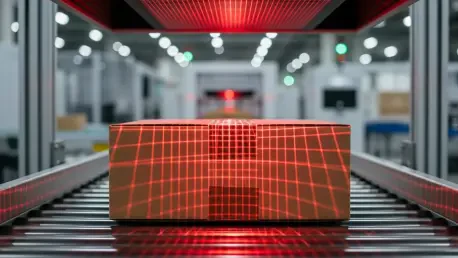

That dual-functionality is really the heart of this system’s elegance. The core technology, a high-speed sorter, doesn’t inherently care about the parcel’s final role; it’s the software and the physical layout around it that create the magic. Imagine a parcel arriving from another city, destined for a different province. Its journey is pure velocity. It’s scanned upon arrival, inducted onto the sorter, and routed directly to an outbound trailer for its next long-haul leg. It might be in the facility for an incredibly short period. Now, contrast that with a parcel intended for local Johannesburg delivery. It hits the same sorter, but the system’s logic routes it to a specific chute designated for a particular delivery route or van. It’s then staged for the local driver. The automation allows both workflows to happen simultaneously and seamlessly, maximizing the efficiency of the building’s footprint and the transportation assets.

The announcement emphasizes integrating “global best practices with local market knowledge.” Can you give us an example of a challenge that might be specific to the South African courier market and how a custom-engineered solution like this would be designed to address it?

From my experience, a common challenge in markets with diverse infrastructure is the sheer variety of parcel types and destinations. You’re not just dealing with standardized boxes going to urban addresses. You have everything from commercial deliveries to small e-commerce packages heading to more remote areas. This is where “local knowledge” becomes critical. The process would begin by analyzing RAM’s specific historical data—what are the shapes, sizes, and weights of their typical parcels? Where do they see the most exceptions? A “global best practice” might be a certain type of sorter, but the “local customization” is engineering the induction points and scanner arrays to handle the polybags and irregularly shaped items that are common in their network. It’s about building a system that doesn’t just work in a perfect lab environment but is robust enough to handle the real-world complexities and operational requirements of RAM’s day-to-day business.

When we talk about scalability, it often brings to mind physical expansion. Beyond just leaving room for more equipment, what specific technological features are likely built into this system to future-proof it for growth?

This is a fantastic point because true scalability is designed in from day one, long before you pour the concrete. Technologically, this means the system is modular. The central software, the brain of the operation, is built to handle far more capacity than is initially needed. The physical sorter might be installed with a certain number of divert chutes, but the framework and control logic are already in place to add more as volume grows. The key performance metrics that signal when it’s time to activate those upgrades are crucial. You’re constantly monitoring things like chute utilization rates and the time parcels spend in buffer zones. When you see that your peak season demand is consistently pushing the system to its designed limits, that’s your data-driven trigger to invest in the next module, confident that the underlying infrastructure is ready for it.

Graeme Lazarus of RAM spoke about enhancing the promise of “accuracy, visibility, and service excellence.” How does a feature like real-time track-and-trace directly translate into a better experience for the end customer?

The impact is monumental because it transforms communication from reactive to proactive. In a legacy system, a customer might see “In Transit” for days. With this end-to-end automation, every scan point within the Isando facility becomes a new piece of information. The customer can see their parcel has been received, sorted, and loaded onto the final delivery van. Think about a common issue: a customer calling to check on a critical delivery. Before, an agent might have had to make several calls to find the parcel. Now, they can look at their screen and say with confidence, “I can see your package was sorted at 8:15 AM and is on van 27 for delivery today.” That level of granular detail builds enormous trust and allows RAM to deliver on that promise of service excellence in a tangible way.

What is your forecast for the adoption of this level of sophisticated automation in emerging CEP markets over the next five years?

I believe we’re at a tipping point. Projects like this one serve as a powerful proof of concept, demonstrating a clear return on investment. The primary drivers are universal: soaring e-commerce volumes and customer expectations that are now global, not local. Over the next five years, I forecast an acceleration in adoption, but with a twist. The innovation won’t just be in massive, central hubs like this one. We’ll see a surge in more scalable, modular automation solutions designed for smaller, regional depots. The technology is becoming more accessible, allowing companies to deploy automation in a more distributed network model. This will be key to meeting the demand for ever-faster delivery times, not just in major cities but across entire national footprints.