The catastrophic financial impact of an unexpected power outage, which can cost a modern semiconductor fabrication plant anywhere from one to five million dollars per hour, has catalyzed a profound shift in how industries perceive their energy infrastructure. No longer just a passive device for measuring consumption and generating a bill, the humble energy meter is being transformed by artificial intelligence and edge analytics into an indispensable strategic asset. In the high-stakes world of advanced manufacturing, where supply chain resilience and operational uptime are paramount, this evolution redefines the meter as a proactive “supply chain stabilizer.” It now provides the critical, high-resolution intelligence necessary for predictive procurement, optimized operational planning, and comprehensive risk mitigation, fundamentally altering its role from a simple counter to a cornerstone of industrial strategy. This transformation is not merely an incremental upgrade but a re-imagining of how energy data integrates into the core of business operations, creating a new symbiotic relationship between energy providers and their most demanding consumers.

A New Breed of Intelligence on the Grid

From Billing Tool to Strategic Node

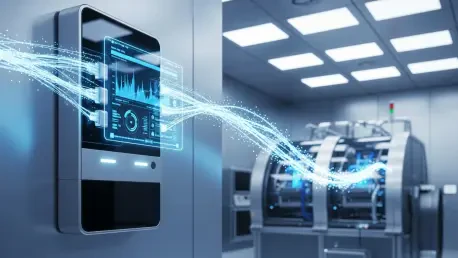

The modern smart meter has shed its identity as a simple utility instrument and emerged as a sophisticated, distributed micro-decision engine. This transformation is driven by the integration of powerful onboard processors, dedicated edge AI chips, and secure, high-speed communication protocols that allow these devices to function as intelligent nodes on the energy grid. Instead of merely collecting and transmitting raw consumption data, they now perform complex, localized analysis in real time. Their core capabilities have expanded to include high-frequency load forecasting, immediate detection of power quality anomalies like voltage sags, and dynamic coordination of Distributed Energy Resources (DERs). This enables them to not only monitor but also actively participate in maintaining grid stability. This leap in functionality turns what was once a one-way street of data collection into a dynamic, two-way conversation between the consumer’s operational environment and the broader energy network, providing an unprecedented level of control and insight.

This evolution from a passive recorder to an active analytical tool marks a pivotal moment for industrial operations, especially in sectors where precision is non-negotiable. For a semiconductor fabrication plant, which can house between 5,000 and 50,000 highly sensitive process tools operating under extremely rigid schedules, the value of this localized intelligence cannot be overstated. The real-time, granular data generated at both the main grid interface and individual tool-level feeders becomes a direct input for the facility’s sophisticated production scheduling algorithms. By providing immediate feedback on energy quality and availability, these intelligent meters help preemptively identify potential disruptions that could compromise a wafer batch. This ensures that the consistent, high-quality energy flow required for stable production is maintained, directly minimizing cycle time variations and safeguarding against costly manufacturing defects, effectively turning energy data into a foundational pillar of operational excellence and supply chain integrity.

The Power of High-Resolution Data

The true value of these advanced meters lies in their ability to provide high-resolution, actionable intelligence that directly informs and strengthens supply chain resilience. For utilities, the data facilitates predictive maintenance on a scale previously unimaginable. AI models analyze continuous streams of information to detect subtle, early-warning signatures of equipment stress that often precede catastrophic failures. This includes identifying transformer fatigue from harmonic distortions, predicting feeder overloads during peak demand, and flagging potential breaker stress long before it leads to an outage. This foresight provides utilities with significant advance warning, allowing them to shift from a reactive to a proactive maintenance posture. This predictive capability translates directly into optimized lead time planning, enabling procurement teams to forecast spare part requirements for critical components like transformers well ahead of time, thereby avoiding costly emergency shipments and ensuring a more stable and reliable grid for their industrial clients.

For the industrial consumers themselves, this data-driven approach fosters a new level of operational control and strategic planning. Inside a semiconductor fab, this high-resolution energy data provides critical insights into the health of essential facility equipment, such as HVAC systems, chillers, and pumps, which are themselves massive energy consumers. By correlating energy consumption patterns with operational performance, facility managers can integrate equipment maintenance schedules directly into their supply chain and production planning. This alignment prevents maintenance activities from disrupting critical production runs and ensures that replacement parts are ordered and on-site precisely when needed. This synergy between energy intelligence and operational logistics minimizes unplanned downtime, reduces the need for large buffer stocks of spare parts, and ultimately enhances the overall efficiency and predictability of the entire manufacturing process, making the supply chain more robust and less susceptible to internal equipment failures.

How AI-Powered Data Fortifies the Supply Chain

Predictive Insights for Proactive Procurement

The application of advanced artificial intelligence models to smart meter data is a game-changer for supply chain management, particularly in the realm of demand forecasting. Sophisticated algorithms, such as Long Short-Term Memory (LSTM) networks, transformer networks, and hybrid ARIMA-ML pipelines, process a multitude of complex variables far beyond simple historical consumption. These models analyze intricate patterns, including specific production cycle timings, peak energy consumption windows tied to manufacturing processes, seasonal demand shifts, and the massive inrush currents generated by the simultaneous start-up of large industrial tools. The result is a highly accurate and granular energy forecast that empowers procurement leaders to make more informed strategic decisions. This foresight enables them to negotiate more favorable and flexible power contracts, develop precise energy-based costing models for their products, and effectively mitigate production delays that could arise from unforeseen energy market volatility or grid constraints.

Beyond forecasting, AI-driven smart metering functions as a sophisticated early warning system for systemic grid instability, allowing for dynamic and proactive risk mitigation. By continuously analyzing data from across the grid, AI can generate dynamic risk maps that highlight specific feeders or segments prone to failure—instabilities that could trigger costly downtime in a connected manufacturing facility. This intelligence is fed into real-time dashboards used for emergency preparedness, enabling plant operators and supply chain managers to take preemptive actions. These actions can include developing contingency plans for rerouting power, strategically shifting non-critical loads to off-peak hours, or activating backup power sources to safeguard sensitive and high-value production batches. For an industry where even a millisecond-level voltage fluctuation can scrap millions of dollars worth of product, this ability to anticipate and neutralize threats before they materialize transforms energy management into a powerful tool for safeguarding assets and ensuring business continuity.

Evidence from the Field

The theoretical advantages of this technology are being validated by tangible, real-world outcomes that demonstrate its profound impact on industrial operations. In a notable case study, a major European utility partnered with a large semiconductor fab to deploy AI-integrated smart meters throughout the industrial zone. The system’s advanced AI analytics successfully identified critical strain on a key transformer 18 days earlier than the utility’s traditional SCADA monitoring systems could. This significant advance warning enabled the utility’s procurement team to reorder the necessary transformer modules proactively, bypassing standard procurement cycles. The results were dramatic: a 28% reduction in component lead times for the utility, a 12% improvement in the fab’s production scheduling adherence due to enhanced grid stability, and, most critically, zero unplanned fab downtime attributed to power quality issues over an eight-month observation period, showcasing a clear return on investment.

A similar success story emerged from an industrial park in India, where a semiconductor fab implemented a comprehensive network of AI-enabled meters extending from the main substation down to individual tool-level feeders. The system’s predictive analytics detected anomalous start-up current spikes in specific chemical-mechanical planarization (CMP) and deposition tools, correctly flagging impending circuit breaker degradation that would have otherwise gone unnoticed until failure. This granular, predictive data was integrated directly into the fab’s Enterprise Resource Planning (ERP) procurement engine, automating the ordering of replacement parts. The impact on the supply chain was significant: spare-part availability for critical electrical components increased by 24%, maintenance response times improved by 22%, and downtime associated with voltage sag events was reduced by an impressive 17%. The park’s head of engineering confirmed this strategic shift, stating, “Intelligence from smart meters now directs our procurement schedule,” affirming the meter’s new role as a central pillar of operational strategy.

A New Paradigm in Industrial Operations

Deeper Integration and Financial Visibility

The fusion of smart meter intelligence with core business operations is poised to become even more deeply integrated, moving beyond predictive maintenance into the realm of proactive operational orchestration. Future applications will feature AI-orchestrated load scheduling, where sophisticated predictive models will actively align a factory’s tool and production schedules with periods of optimal grid stability and lower energy costs. This dynamic scheduling will allow energy-intensive processes to run when the grid is most robust and electricity is most affordable, reducing both operational risk and expenditure. Furthermore, this data will feed into the next generation of business intelligence tools, creating real-time dashboards for financial executives. These platforms will directly quantify the return on investment from enhanced energy intelligence, translating abstract concepts like risk reduction and operational resilience into clear, compelling financial metrics such as reduced cost-per-unit and improved asset utilization.

This move toward quantifiable results will cement the smart meter’s position as a vital asset for securing a competitive advantage in a volatile global market. By providing a direct line of sight from energy consumption patterns to financial outcomes, these systems will empower C-suite executives to make more informed, data-driven decisions regarding long-term vendor agreements and capital expenditures. For instance, procurement leaders will be able to evaluate the real-world energy efficiency and reliability of supplier components under actual load conditions, leading to smarter purchasing choices. This new layer of intelligence will also dramatically reduce the need for maintaining extensive buffer stocks of spare parts, freeing up capital and reducing carrying costs. Ultimately, this tight integration transforms energy management from a reactive operational cost center into a proactive, strategic function that directly contributes to the bottom line and strengthens the company’s market position.

The Dawn of Digital Twins and Edge AI

Looking forward, the evolution of this technology will be defined by the creation of highly accurate “digital twins”—virtual simulations of both the energy grid and the industrial facilities it serves. Utilities and their industrial partners will leverage the rich data streams from smart meters to build these sophisticated models, which can be used to test equipment stress scenarios and evaluate the potential impact of operational changes before any physical assets are deployed or major investments are made. For example, a fab could simulate the effect of adding a new production line on the local grid segment, identifying potential vulnerabilities and allowing for preemptive infrastructure upgrades. This capability transforms capital planning from a process based on historical averages to a dynamic, forward-looking strategy based on precise, predictive modeling, de-risking major business decisions and optimizing resource allocation.

At the same time, the hardware itself will continue to advance, with next-generation meters hosting more powerful edge AI models capable of performing complex, independent diagnostics on-site. These advanced meters will be able to identify and analyze highly specific power quality issues, such as the harmonic distortions that are particularly damaging to sensitive advanced lithography tools, without needing to send vast amounts of data back to a central server. This on-site intelligence enables faster response times and more tailored solutions, creating a truly symbiotic, data-driven relationship between energy suppliers and consumers. This technology, by providing predictive, granular, and actionable intelligence, empowered procurement directors, supply chain strategists, and engineers to make informed, proactive decisions. These choices were essential for maintaining production schedules, optimizing lead times, and securing a competitive advantage in industries where high-quality, uninterrupted power was paramount, solidifying the smart meter as a foundational technology for stabilizing critical global supply chains.