The hum of autonomous systems and the glow of predictive analytics dashboards are no longer novelties confined to innovation labs; they now represent the established pulse of modern logistics operations. For years, the industry approached automation and digital transformation with cautious curiosity, launching countless pilot programs to test the potential of new technologies. That era of tentative experimentation is decisively over. The central question is no longer “What if we try this?” but rather “How do we deploy this everywhere, now?” This year marks a critical turning point where proven technologies are moving from the periphery of strategy to the very core of execution, driven by an urgent need for resilience, efficiency, and competitive advantage.

The End of Experimentation What Happens When the Trial Runs Are Over

The logistics sector has officially graduated from its prolonged phase of technological trials. The industry-wide conversation has pivoted from exploring possibilities to implementing certainties. For years, warehouses and distribution centers served as testing grounds for isolated pieces of technology—a single robotic arm here, a small fleet of autonomous mobile robots (AMRs) there. These pilots served their purpose, demonstrating proof of concept and generating valuable data.

However, the landscape has fundamentally shifted. The learnings from these trials have matured into a clear understanding of what works, what scales, and what delivers tangible returns. Consequently, logistics leaders are now focused on enterprise-wide rollouts, integrating technology not as an experiment but as a foundational element of their operational infrastructure. The focus is on achieving cohesive, end-to-end automation rather than celebrating isolated successes.

The Pressures Forcing the Pivot Why Scaling Is No Longer Optional

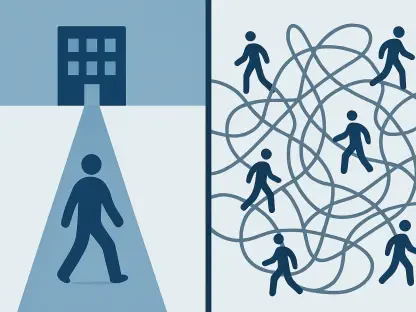

This transition is not merely a matter of choice; it is a response to a convergence of powerful external and internal forces. Foremost among these is the labor imperative. Persistent workforce availability challenges and rising labor costs have made augmenting human capabilities a critical priority. Automation is now seen as the most viable path to enhancing productivity and creating safer, more ergonomic work environments for employees.

Simultaneously, the “expectation economy” continues to reshape customer demands. Consumers and businesses alike now expect unprecedented levels of speed, accuracy, and transparency in the supply chain. Meeting these escalating standards is impossible with legacy systems and manual processes. Furthermore, the sustainability mandate, driven by both regulatory pressure and consumer sentiment, compels operators to build greener, more efficient supply chains. Scaled technology provides the tools to optimize energy consumption, maximize facility space, and reduce waste.

Key Pillars of Scaled Execution How Technology Is Being Deployed

The move to full-scale implementation is characterized by several dominant trends. The most significant is the evolution from deploying isolated bots to engineering enterprise-wide automation. For instance, Yusen Logistics now utilizes over 165 shelf-to-person robots as a single, cohesive system, making it a business-critical component of its fulfillment operation. Similarly, THG Fulfil’s reliance on goods-to-person robotics is not a trial but a foundational strategy for managing high-volume e-commerce orders with precision.

Beyond physical machinery, an intelligence layer powered by AI and data analytics has gone mainstream. Traditional Warehouse Management Systems (WMS) that react to events are being replaced by proactive, AI-driven platforms. These systems enable predictive decision-making, optimizing inventory placement, labor allocation, and workflow in real-time. This transforms data from a tool for backward-looking reports into a source of immediate, actionable intelligence for operational control.

The pinnacle of this evolution is the rise of integrated ecosystems. Forward-thinking organizations are no longer procuring technology in silos. Instead, they are implementing unified architectures that combine robotics, automated storage and retrieval systems (AS/RS), and software into a single, cohesive solution. The state-of-the-art distribution center at Portwest exemplifies this, where different forms of automation work in concert to achieve maximum throughput and operational fluidity.

Findings From the Front Lines A Human Centric and Sustainable Reality

As these technologies become embedded in daily operations, key insights are emerging from the front lines. Analysis reveals a predominantly human-centric approach to automation. Contrary to early fears, technology is being strategically deployed to support the human workforce rather than replace it. Automation is handling the most physically demanding, repetitive, and strenuous tasks, which reduces physical strain, improves workplace safety, and elevates employees to higher-value roles involving oversight, problem-solving, and quality control.

Industry analysis also confirms that sustainability has transitioned from a high-level corporate ambition to a core operational imperative. This shift is driven by the practical benefits of scaled technology. Energy-efficient automation infrastructure directly reduces a facility’s carbon footprint. Moreover, the ability of AS/RS and robotic systems to densify storage allows companies to maximize the capacity of existing facilities, deferring or eliminating the need for new construction and its associated environmental impact.

The Strategic Playbook A Framework for Successful Implementation

For logistics leaders navigating this new era, a clear strategic playbook has emerged. The first principle is to prioritize integrated solutions over siloed technologies. Success hinges on building a cohesive system where hardware and software are designed to work in unison to achieve overarching business goals, breaking down the traditional barriers between different functional areas of the warehouse.

A second critical strategy is to embrace data-driven decisions over intuition. Leveraging AI and advanced analytics allows operators to move from a reactive posture of solving problems as they arise to a proactive one of managing operations based on predictive insights. Finally, cultivating long-term strategic partnerships has become more important than seeking short-term fixes. Selecting technology partners who can support enterprise-wide scalability and adapt to future business needs is essential for sustained success.

The pivot from isolated pilots to scaled execution was not just a trend; it became the defining characteristic of leading logistics operations. Organizations that successfully made this transition did so by treating technology not as a collection of tools, but as an integrated system woven into the fabric of their business. They demonstrated that the true value of automation and AI was unlocked through strategic, enterprise-wide deployment, which ultimately built the resilient, intelligent, and sustainable supply chains that the modern economy demanded.