The tightrope walk of a finance marketing leader involves balancing audacious creative campaigns with the unyielding gravity of regulatory compliance and stringent ROI expectations. In this high-stakes environment, the operational software underpinning marketing efforts is not merely a tool for

The persistent gap between the sheer volume of marketing activities an organization undertakes and the tangible business results it achieves often points to a fundamental flaw not in execution, but in orchestration. Marketing Program Management (MPM) emerges as a strategic discipline designed to

Many organizations have experienced the frustration of investing significant time and resources into video content that appears flawless on paper, only to see the results fall disappointingly short of expectations. The concepts are strong, the production quality is high, and the entire team feels

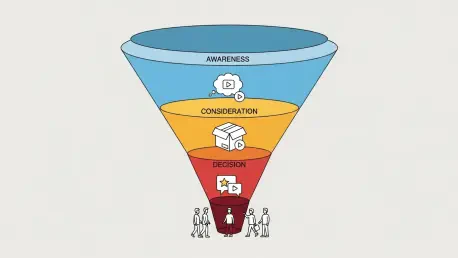

Customer experience has reached a critical inflection point where workflow and CX automation are no longer niche tools for efficiency but are central topics in boardroom discussions. Business leaders are confronting a trio of persistent challenges: alarming rates of customer drop-off, frustratingly

The disconnect between a brilliant marketing strategy and its real-world execution often lies hidden within the vast, unmanaged space of day-to-day operational chaos. As the industry accelerates toward 2026, a consensus is emerging among thought leaders and high-performance teams: the most

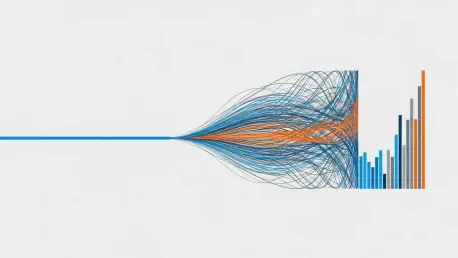

The path from a project's starting line to its finish is rarely a straight one, often winding through a landscape of unpredictable variables and unforeseen challenges. For project managers, navigating this uncertainty is not a matter of guesswork but of strategic analysis. The Project Management