I’m thrilled to sit down with Marco Gaietti, a veteran in the field of robotics and warehouse automation with decades of experience in business management. Marco’s insights into strategic operations and cutting-edge technology have helped shape the future of logistics. Today, we’re diving into the transformative world of Autonomous Mobile Robots (AMRs), exploring how they’re revolutionizing warehouses, the role of AI in enhancing their capabilities, and what the future holds for this dynamic industry.

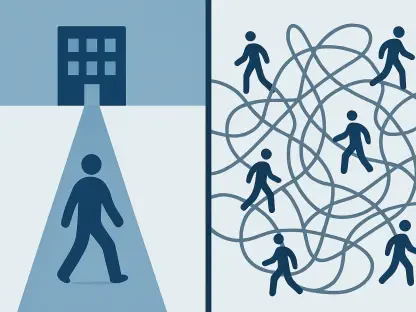

How would you describe Autonomous Mobile Robots (AMRs) and what sets them apart from the older Automated Guided Vehicles (AGVs)?

AMRs are a new breed of robots designed for warehouses, capable of moving around independently without being tied to fixed paths. Unlike AGVs, which depend on things like magnetic strips or wires embedded in the floor, AMRs use sensors and software to navigate dynamically. This means they can dodge obstacles and adapt to changes in real-time, offering a level of freedom that AGVs just can’t match.

Can you explain how AMRs manage to navigate effectively in the chaotic environment of a busy warehouse?

Absolutely. AMRs rely on a combination of advanced sensors, cameras, and mapping technology to understand their surroundings. They create a virtual map of the warehouse and use real-time data to adjust their routes, avoiding workers, equipment, or unexpected obstacles. It’s like having a GPS system that’s constantly updating based on what’s happening around them.

Why do you think the flexibility of AMRs is such a significant advantage over traditional automation systems?

The flexibility of AMRs is a game-changer because warehouses are rarely static. Traditional systems often require fixed setups, which can be a headache to modify. AMRs, on the other hand, can be reprogrammed or redeployed quickly to handle new tasks or layouts. This adaptability means businesses can respond to changes without massive overhauls or downtime.

How do AMRs allow warehouses to adopt automation without tearing apart their existing infrastructure?

One of the best things about AMRs is that they don’t demand major changes to a warehouse’s setup. Since they navigate autonomously, there’s no need for installing tracks or redesigning the floor plan. They can work alongside existing systems and human workers, integrating seamlessly into operations without the costly disruptions that older automation often requires.

What are some of the warehouse tasks that AMRs are capable of handling, from the basic to the more intricate ones?

AMRs are incredibly versatile. On the simpler side, they can transport goods from one point to another, like moving pallets or bins. But they’re also built for more complex tasks, such as order picking, where they assist workers by guiding them to specific items or even handling the selection process in some setups. Their ability to tackle a range of jobs makes them invaluable.

How do AMRs adapt to the ups and downs of warehouse demands, like during holiday rushes or quieter times?

AMRs are designed to scale with demand. During peak times, like the holiday season, you can deploy more robots to handle the increased workload. When things slow down, you can reduce their numbers or reassign them to other tasks. This scalability ensures warehouses aren’t stuck with unused equipment or overwhelmed during busy periods.

Can you break down the Robots as a Service subscription model and why it’s appealing to businesses?

Robots as a Service is essentially a rental model for AMRs. Instead of buying the robots outright, businesses subscribe to use them, paying for what they need when they need it. This approach lowers upfront costs, offers flexibility to scale operations, and lets companies focus on their core business rather than managing robot ownership.

What financial benefits come from keeping AMRs off a company’s balance sheet through such models?

Keeping AMRs off the balance sheet is a big win financially. It means businesses don’t have to record them as capital expenses, which can impact debt ratios and financial statements. Instead, they’re treated as operational costs, often more manageable and predictable, freeing up capital for other investments or needs.

How does artificial intelligence enhance the performance of AMRs in modern warehouses?

AI is the brain behind AMRs. It processes data from sensors to make split-second decisions, optimizing routes and improving efficiency. AI also enables robots to learn from their environment over time, so they get better at predicting obstacles or finding faster paths, ultimately boosting productivity in the warehouse.

What specific ways does AI improve the navigation or decision-making abilities of these robots?

AI takes navigation to the next level by analyzing real-time data to choose the most efficient routes, even in crowded or changing spaces. For decision-making, it helps robots prioritize tasks based on urgency or location, ensuring they’re always working on what’s most critical. It’s like giving them a strategic mind to tackle complex logistics challenges.

With thousands of robots deployed, what kind of impact have you seen AMRs have on warehouse operations?

The impact is staggering. Warehouses using AMRs often see productivity double or even triple, as robots handle repetitive tasks, letting human workers focus on more skilled roles. Error rates drop, delivery times speed up, and overall costs decrease. It’s a complete transformation of how goods move through these spaces.

What are some common hurdles warehouses face when bringing in AMRs, and how are these challenges addressed?

One big hurdle is integrating AMRs with existing systems and workflows—there’s often a learning curve for staff. Another is ensuring the robots can handle the unique layout or quirks of a specific warehouse. These challenges are tackled through thorough training programs, customizable robot software, and close collaboration with vendors to tailor solutions to each facility’s needs.

Looking globally, which regions do you see as having the most potential for AMR growth in the coming years?

North America and Europe are poised for huge growth. Both regions have a strong logistics base, high labor costs, and a push for efficiency, making AMRs an attractive solution. Plus, there’s increasing demand for faster delivery, which automation can support. These markets are ripe for expansion as the technology becomes more accessible.

What exciting innovations or new products are on the horizon for pushing warehouse automation further?

We’re seeing a lot of focus on enhancing robot collaboration with humans, making interactions even smoother. There’s also work on multi-function robots that can handle a wider variety of tasks, from picking to packing. And advancements in AI are set to make robots even smarter, with better predictive capabilities for inventory management and demand forecasting.

How do you think the logistics industry will evolve over the next few years with the rise of AMRs and similar technologies?

I believe we’re on the cusp of a logistics revolution. AMRs will become the backbone of warehouses, driving unprecedented speed and accuracy. We’ll see supply chains become more responsive, with real-time data and automation shrinking delivery windows. The industry will shift toward greater sustainability too, as optimized operations cut energy use and waste. It’s an exciting time, and I think the next few years will redefine how goods move around the world.