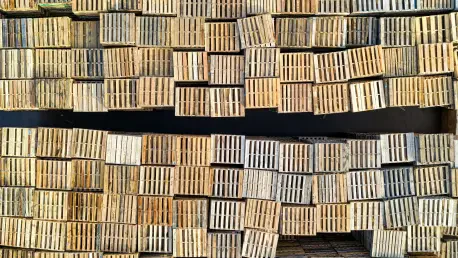

How can something as commonplace as a wooden pallet become a catalyst for environmental change in a high-stakes industry like logistics? Picture a sprawling supply chain where trucks often travel empty on return trips, burning fuel and emitting carbon without purpose, while Scott Pallets, a key player within the BSW Group, flips this wasteful norm on its head with bold strategies that cut emissions and redefine efficiency. This story uncovers how a pallet supplier is leading a sustainability revolution, proving that even routine operations hold untapped potential for planetary impact.

Why Logistics Needs a Sustainability Overhaul

The logistics sector stands as one of the largest contributors to global greenhouse gas emissions, accounting for nearly a quarter of the transport industry’s carbon footprint, according to recent studies. With growing scrutiny from consumers and regulators, companies face intense pressure to curb inefficiencies like empty miles and excessive fuel consumption. This urgent need for change sets the stage for innovative players to step up, demonstrating that sustainable practices are not just ethical but also essential for long-term business viability.

Scott Pallets emerges as a frontrunner in this critical shift, addressing systemic challenges with actionable solutions. Their efforts resonate with a broader industry trend toward greener supply chains, where every decision—down to how a truck is loaded—can ripple outward to influence environmental outcomes. This narrative isn’t just about one company; it’s about a pivotal moment where logistics must evolve to meet the demands of a climate-conscious world.

Cutting Carbon One Trip at a Time

At the heart of Scott Pallets’ transformation lies a deceptively simple ideno truck should return empty. Their backloading program ensures that after delivering pallets, vehicles are reloaded with BSW Timber’s sawn products for the return journey, often between key sites like Newbridge-on-Wye and Barry. Since tracking began, hundreds of trips have been optimized this way, slashing fuel use and reducing carbon emissions by a measurable margin.

This initiative isn’t a one-off; it’s a systemic rethink of asset utilization. By integrating timber deliveries into return routes, the company not only minimizes environmental harm but also drives down operational costs, creating a win-win for both planet and profit. Such precision in logistics planning highlights how small tweaks can yield outsized benefits when applied at scale across a network.

Turning Waste into Value

Beyond optimizing trips, Scott Pallets is tackling another pressing issue: waste. At their Ellesmere Port site, a specialized walking floor vehicle collects scrap wood that would otherwise be discarded, transforming it into biomass fuel. This material is then supplied to Shotton Mill in Deeside, feeding into a circular economy that repurposes leftovers into renewable energy.

This waste-to-value approach showcases a commitment to sustainability that extends past mere transportation. Partnerships with internal BSW Group entities, such as Tilhill Forestry, amplify these efforts, ensuring that every byproduct serves a purpose. The result is a model that not only reduces landfill contributions but also supports alternative energy solutions, setting a standard for resourcefulness in the industry.

Collaboration as the Backbone of Change

Strategic alliances form the bedrock of Scott Pallets’ green initiatives, proving that no company can achieve sustainability alone. By working closely with haulage partners like H&R Gray and Johnsons Haulage, they’ve reconfigured load presentations and optimized trailer deployment, ensuring maximum efficiency at customer sites. These collaborations streamline operations while minimizing fuel waste across the supply chain.

Internally, synergy with BSW Timber and other group entities fosters innovation at every turn. A spokesperson from the company emphasized, “Every partnership pushes us closer to a model where sustainability and business goals align perfectly.” This collective drive underscores a shared vision, where external and internal stakeholders unite to tackle environmental challenges with practical, scalable solutions.

A Blueprint for Industry-Wide Impact

The strategies employed by Scott Pallets offer actionable lessons for others in logistics. Start with vehicle utilization—adopt backloading practices to ensure every mile serves a dual purpose, mirroring their integration of timber returns. Next, explore opportunities to convert waste into resources, as seen with their biomass initiative, which turns scrap into something valuable rather than a burden.

Finally, prioritize partnerships that enhance efficiency, whether through load optimization with hauliers or cross-departmental efforts within a larger organization. These steps, grounded in real-world success, provide a roadmap for balancing profitability with environmental stewardship. The logistics sector can look to such examples as proof that sustainability is achievable, even in an industry often criticized for its ecological footprint.

Reflecting on a Sustainable Legacy

Looking back, Scott Pallets carved a path that intertwined operational excellence with environmental responsibility. Their journey through backloading, waste repurposing, and collaborative innovation laid down a marker for what logistics could become. Each initiative stood as a testament to the power of intentional, practical change in an industry long overdue for reform.

For the future, the challenge shifts to scaling these efforts across broader networks and inspiring others to follow suit. Industry leaders are encouraged to adopt similar frameworks, focusing on efficiency and partnerships as cornerstones of progress. The next steps involve not just sustaining momentum but accelerating it, ensuring that green logistics becomes the norm rather than the exception.