The architectural landscape of modern logistics centers is undergoing a quiet but transformative evolution, driven by an relentless pursuit of efficiency that has fundamentally altered the very skeleton of these massive structures. In an effort to maximize floor space and streamline the flow of automated and human-operated vehicles, contemporary warehouse design increasingly favors fewer, yet substantially larger and more varied, structural columns. This shift away from the uniform pillars of the past introduces a significant safety challenge, as the diverse array of column sizes and shapes within a single facility renders traditional, one-size-fits-all protective solutions ineffective. The risk of a collision with these critical supports carries catastrophic potential, threatening not only expensive equipment and inventory but the structural integrity of the entire building, making a more adaptable and intelligent approach to asset protection an operational necessity rather than a mere precaution.

A Modular Answer to Architectural Diversity

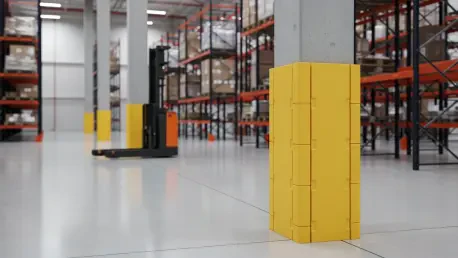

In direct response to the complex demands of new-build and retrofitted warehouses, the Column Sentry FIT System introduces a sophisticated, modular approach to impact protection that prizes flexibility above all else. The system is engineered around two core components: Small Fit and Medium Fit modules, which are designed to be interlinked in various combinations to encase a wide spectrum of column sizes. A key innovation within this system is the “Fit Combo,” a configuration utilizing two small and two medium pieces to form a robust rectangular guard. This specific arrangement is tailored to protect the wide, blade-like columns that are becoming a common feature in modern distribution centers, a design challenge that has previously lacked a dedicated, form-fitting solution. By moving beyond a rigid, one-size mentality, this adaptable framework allows facility managers to create a precise protective barrier, ensuring a snug fit that maximizes energy absorption upon impact and eliminates the dangerous gaps left by ill-fitting, older-style protectors.

The true strength of this modular concept is fully realized through its capacity for near-infinite expansion, which is achieved with a series of dedicated extension pieces. These components seamlessly integrate with the standard Small and Medium Fit modules, allowing safety managers to precisely lengthen any side of the protector to match exact column dimensions. This capability is crucial for accommodating the non-standard and often oversized columns found in today’s logistics hubs. Whether dealing with a large square support or an unusually long rectangular pillar, the system can be scaled to provide complete, uninterrupted coverage. This eliminates the need for compromise or the risky practice of using multiple, misaligned guards. The result is a single, cohesive protective unit that is perfectly tailored to the asset it surrounds, ensuring that the protective integrity is maintained across the entire surface and that impact forces are properly dissipated, regardless of the column’s unique size or orientation.

Bridging The Gap Between Complexity and Usability

While a highly adaptable and modular system offers unparalleled protection, it can also introduce a layer of complexity for the end-user, potentially creating a barrier to adoption. Recognizing that facility managers need a straightforward path from problem to solution, a powerful online configurator tool was developed to demystify the specification process entirely. This intuitive, web-based platform serves as an intelligent guide, allowing users to simply input the unique dimensions and total quantity of the columns they need to protect. The software’s sophisticated algorithm then instantly processes this information, performing all the necessary calculations to determine the precise bill of materials required for the job. It automatically specifies the exact number of Small Fit and Medium Fit modules, as well as any necessary extension pieces, removing all guesswork and the potential for human error from the planning phase of a critical safety installation.

The configurator tool does more than just generate a parts list; it provides a comprehensive and transparent procurement experience designed to overcome common purchasing objections. Once the column dimensions are entered, the platform generates a clear, visual diagram of the final assembled protector, giving the user an immediate and accurate representation of how the solution will fit their specific structural supports. Simultaneously, the tool integrates with a reseller portal to produce an itemized, fully costed quote. This transparent, all-in-one process directly addresses concerns about budget uncertainty, questions about proper fit, and the feeling that a site’s needs are too unique for a standard product. By making the entire journey—from measurement to final quote—simple, visual, and immediate, the system effectively dismantled the reluctance to invest in essential safety infrastructure, proving that advanced protection could also be accessible.