In modern manufacturing, rapid business growth often presents a paradoxical challenge, as the very success that drives expansion can strain a company’s physical and logistical infrastructure to its breaking point. For Volpak, a Coesia company specializing in flexible packaging solutions, the global popularity of flexible pouches fueled an unprecedented increase in production volumes at its historic Barcelona facility. This surge created a critical bottleneck within the plant’s multi-level layout, where traditional logistics could no longer keep pace with the demand for internal parts movement. The situation demanded a fundamental rethinking of its operational framework, forcing the company to innovate within its existing footprint. The solution was a comprehensive intralogistics transformation, integrating lean manufacturing principles with advanced automation and data-driven process redesign to build a smarter, more efficient factory capable of sustaining its growth trajectory. This strategic overhaul represents a shift from a conventional ‘push’ logistics model to a sophisticated ‘pull’ system, driven directly by real-time production needs.

A Strategic Shift to Demand-Driven Logistics

Overcoming Physical Constraints Through Vertical Integration

To address the significant spatial limitations of its two-level factory, Volpak engineered an innovative vertical material-flow system that fundamentally transformed its internal logistics. The existing multi-level structure had become a major impediment, complicating the movement of materials between storage and assembly areas and creating inefficiencies that could no longer be ignored. The new architecture directly confronts this challenge by maximizing the use of vertical space. It incorporates a network of vertical conveyors and high-density storage solutions that seamlessly link the warehouse, quality inspection zones, and the main assembly floor. This multi-level transport system is designed for precision and speed, minimizing travel time for components while drastically increasing storage capacity. By building upwards, the company not only optimized its current footprint but also created a scalable infrastructure that could accommodate future expansion without requiring physical plant growth, demonstrating a forward-thinking approach to industrial architecture and process flow.

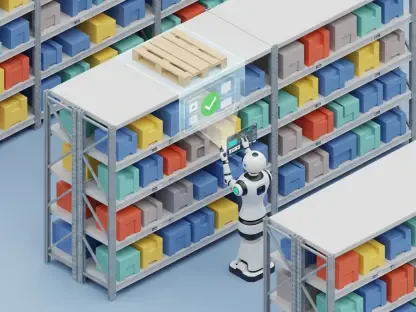

The Role of Autonomous Mobile Robots

At the heart of Volpak’s modernized intralogistics is a fleet of Autonomous Mobile Robots (AMRs) that orchestrates the seamless, just-in-time delivery of materials across the facility. These intelligent vehicles are fully synchronized with a new, fully automated warehouse, operating as the crucial link between inventory and production. When an assembly line signals a need for specific components, the warehouse management system automatically dispatches an AMR to retrieve the required parts and transport them directly to the point of use. This eliminates the manual labor and potential delays associated with traditional material handling. The AMRs navigate the factory floor with precision, ensuring that assembly teams receive exactly what they need, precisely when they need it. This automated, demand-driven approach not only accelerates the production cycle but also enhances safety by reducing forklift traffic and creates a cleaner, more organized work environment. The fleet represents a cornerstone of the company’s lean automation strategy, enabling a fluid and responsive manufacturing ecosystem.

Data-Driven Optimization and Lean Principles

Intelligent Inventory Management

A cornerstone of the operational transformation was a meticulous, data-driven analysis of the company’s extensive inventory, which comprises more than 40,000 Stock Keeping Units (SKUs). By classifying these components into A-B-C categories based on their movement frequency and demand, Volpak developed a highly optimized storage strategy. High-demand ‘A’ parts, which astonishingly account for 80% of all material movements, were strategically relocated to high-throughput, easily accessible areas within the automated warehouse. In contrast, lower-demand ‘B’ and ‘C’ items were assigned to high-density, deep-rack storage systems, maximizing space without compromising access when needed. This intelligent segmentation was instrumental in designing the new automated storage and retrieval system, which has yielded an impressive 50% increase in storage capacity within the same physical footprint. This data-first approach not only solved the immediate capacity crisis but also provided the inherent scalability required to support projected business growth for the coming years.

Embracing One-Piece Flow

The new automated system was engineered to fully support Volpak’s commitment to its ‘Lean Transformation’ path, specifically enabling a ‘one-piece flow’ manufacturing logic. This lean principle dictates that work progresses smoothly from one stage to the next without interruption or delay. In this context, production orders are now prepared and delivered as complete, consolidated kits. When a new assembly job is initiated, the system automatically gathers all necessary components and delivers them together to the workstation. This method drastically reduces the waiting times and material handling that plagued the previous system, where operators often had to search for individual parts. It ensures that assembly teams have every component they need to begin work immediately, fostering a faster, cleaner, and more ergonomic production process. By minimizing unnecessary movement and streamlining the workflow, this approach has significantly enhanced operator efficiency and safety, marking a pivotal step in the facility’s evolution toward operational excellence.

A Scalable Blueprint for Future Factories

The successful integration of lean automation and data-driven logistics at the Barcelona plant did more than solve a pressing operational challenge; it established a new, scalable benchmark for operational excellence across the Coesia Group. Entirely designed and implemented by Volpak’s internal teams with strategic support from Coesia, the project stands as a testament to the power of in-house innovation. The transformation created a highly efficient, responsive, and ergonomic manufacturing environment prepared for the demands of Industry 4.0. This achievement positioned the facility as a reference model, providing a proven blueprint for future modernization projects aimed at building smarter, more agile factories capable of thriving in a competitive global market.