Setting the Stage for Modern Logistics

Imagine a sprawling warehouse where thousands of orders are processed daily, yet not a single human worker is in sight for picking or packing. This is no longer a distant vision but a reality driven by warehouse automation systems, a transformative force in the logistics and supply chain sector that has reshaped how businesses operate. With e-commerce sales continuing to skyrocket, businesses face immense pressure to deliver goods faster and more accurately than ever before. Automation has emerged as the backbone of this high-speed environment, promising efficiency and precision where manual labor once struggled to keep pace. This review dives into the core of these systems, exploring their capabilities and impact on modern industry.

The relevance of warehouse automation extends beyond mere speed, touching on cost reduction and scalability in an era where consumer expectations are unrelenting. These systems integrate robotics, software, and advanced machinery to streamline operations from inventory management to order fulfillment. Their rise aligns with broader technological trends, positioning them as a critical component in the digital transformation of industries worldwide. What follows is an in-depth look at how these technologies function, their standout features, and the real-world implications for businesses aiming to stay competitive.

Analyzing the Core Features of Automation Technology

Robotics and Automated Sorting Capabilities

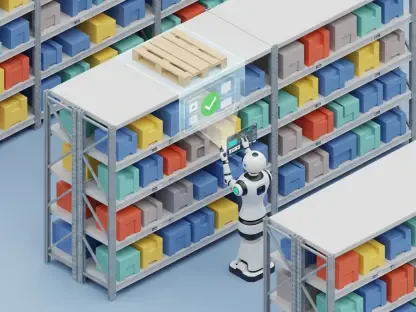

At the heart of warehouse automation lies robotics, a game-changer in handling repetitive and labor-intensive tasks. Systems like OPEX Corporation’s Sure Sort with Xtract exemplify this innovation, automating order sorting, retrieval, and packing with remarkable precision. These robots can process a vast array of items, from small parcels to bulk goods, reducing human error and boosting throughput. Their ability to operate continuously without fatigue sets a new standard for operational efficiency, making them indispensable in high-volume environments.

Performance metrics for robotic systems often highlight speed and adaptability as key strengths. For instance, advanced sorting solutions can handle thousands of items per hour, a feat unattainable by manual labor alone. Scalability also plays a pivotal role, as these technologies can be tailored to fit the needs of both small warehouses and massive distribution centers. This flexibility ensures that businesses can ramp up operations during peak seasons without overhauling their entire setup, a critical advantage in dynamic markets.

Beyond raw performance, the integration of robotics into existing workflows demonstrates a thoughtful approach to modernization. These systems are designed to work alongside human operators when needed, ensuring a balanced transition rather than a complete displacement of labor. The focus on seamless operation underscores why robotics has become a cornerstone of warehouse automation, driving productivity to unprecedented levels.

Integration and Scalability in System Design

A defining feature of modern warehouse automation is its ability to integrate with pre-existing infrastructure, minimizing disruption during implementation. Whether it’s syncing with legacy inventory software or connecting to conveyor belts, these systems offer plug-and-play solutions that adapt to diverse setups. This compatibility reduces downtime and allows businesses to modernize without starting from scratch, a practical consideration for cost-conscious operations.

Scalability remains another standout attribute, catering to enterprises of varying sizes. From small-to-medium businesses managing seasonal spikes to large corporations handling global supply chains, automation systems can be customized to match demand. Real-world examples, such as OPEX’s deployments across different sectors, show how modular designs enable gradual expansion, ensuring that growth doesn’t outpace technological capacity. This adaptability is vital for maintaining a competitive edge in fluctuating markets.

Technical aspects, such as software interoperability, further enhance the appeal of these systems. Advanced platforms can communicate with multiple tools, from warehouse management systems to customer relationship software, creating a cohesive operational ecosystem. This level of integration not only streamlines processes but also provides actionable data insights, empowering businesses to make informed decisions about inventory and logistics.

Performance and Industry Impact

Cutting-Edge Innovations Shaping the Market

Recent advancements in warehouse automation have introduced AI-driven analytics and machine learning, pushing the boundaries of what these systems can achieve. Predictive logistics, powered by intelligent algorithms, allows warehouses to anticipate demand surges and optimize stock levels proactively. This shift toward data-centric operations marks a significant leap, as businesses can now minimize waste and improve turnaround times with pinpoint accuracy.

Emerging trends also point to a growing appetite for end-to-end automation, especially in e-commerce, where speed is non-negotiable. Solutions that cover every step—from receiving goods to shipping orders—are gaining traction, reducing the need for multiple disjointed tools. Additionally, sustainability has become a focal point, with energy-efficient systems addressing environmental concerns while cutting operational costs. Companies like OPEX are at the forefront, innovating to align with these industry priorities through smarter, greener technologies.

The behavioral shift within the sector reflects a broader recognition of automation as a strategic asset rather than a luxury. Businesses are increasingly investing in systems that promise long-term value, driven by the need to stay agile in a globalized economy. This trend toward comprehensive, sustainable solutions indicates a maturing market, one where technology and business goals are more aligned than ever.

Real-World Applications and Measurable Outcomes

Across industries like retail, e-commerce, and manufacturing, warehouse automation has proven its worth through tangible results. Major players, including many Fortune 100 companies in the US, have adopted solutions from providers like OPEX to revamp their logistics frameworks. These deployments often result in dramatic improvements, such as slashing order fulfillment times by significant margins, which directly boosts customer satisfaction.

Small-to-medium enterprises also benefit, leveraging automation to punch above their weight in competitive markets. By automating key processes, these businesses achieve cost reductions that free up capital for growth initiatives. A notable case involves a mid-sized retailer that integrated automated sorting systems, cutting labor expenses while meeting holiday demand surges without delays—an outcome that highlights the democratizing potential of this technology.

The broader impact on operational efficiency cannot be overstated. Automation delivers consistency in environments where human error can be costly, ensuring that inventory discrepancies and shipping mistakes become rare occurrences. These measurable benefits, from lower overheads to faster delivery cycles, underscore why adoption rates continue to climb across diverse sectors, reshaping how goods move from warehouse to consumer.

Verdict on Warehouse Automation Systems

Reflecting on the detailed exploration of warehouse automation systems, it becomes clear that this technology has redefined logistics with its blend of robotics, integration, and innovative trends. The performance of solutions like those from OPEX has demonstrated exceptional speed and scalability, while real-world applications have confirmed their ability to drive efficiency across varied industries. Challenges such as high initial costs and integration complexities have been acknowledged, yet the industry has shown resilience in addressing these through modular designs and customer support.

Looking ahead, businesses that have embraced automation find themselves better positioned to navigate the demands of a fast-paced market, but the journey doesn’t end there. The next steps involve exploring hybrid models that balance human expertise with machine precision, ensuring a workforce equipped for collaboration with advanced systems. Additionally, prioritizing partnerships with providers offering localized support could ease adoption in new regions, paving the way for broader global impact. Warehouse automation has laid a robust foundation, and its continued evolution promises to unlock even greater potential for operational excellence.