What happens when a small German town becomes the epicenter of industrial innovation? In Weißenburg, a quiet region in Bavaria, DOTLUX GmbH is answering that question with a groundbreaking move: the launch of a fully automated logistics facility that promises to redefine warehouse operations by May of next year. This project blends cutting-edge technology with sustainability, offering a glimpse into the future of manufacturing. This isn’t just about pallets and conveyors; it’s about transforming an entire community’s economic landscape.

A New Era in Weißenburg

Nestled in the heart of Bavaria, Weißenburg has long been a hub of modest industrial activity. Now, with DOTLUX’s ambitious project, the town stands on the brink of a technological revolution. The company, a leader in LED lighting solutions, has embarked on constructing a 1,450-square-meter automated warehouse, signaling a shift toward modernity that could inspire similar transformations across rural Germany.

This development isn’t merely a corporate upgrade; it’s a lifeline for a region grappling with economic stagnation. By introducing automation on such a scale, DOTLUX aims to boost efficiency and create a ripple effect of opportunity, potentially attracting other businesses to follow suit. The project, set to go live next spring, positions Weißenburg as a potential model for small-town industrial revival.

The significance of this initiative extends beyond local borders. It reflects a growing recognition that even mid-sized firms must adapt to global challenges through innovation. As DOTLUX paves the way, the spotlight turns to how this facility could redefine expectations for logistics in less urbanized areas, proving that progress isn’t reserved for major cities.

Why Automation Is Critical Today

In today’s fast-paced market, mid-sized manufacturers face relentless pressure from labor shortages and escalating customer expectations. For DOTLUX, based in Weißenburg, the challenge is compounded by a burgeoning product lineup and increasing SKU complexity, which have overwhelmed traditional warehousing methods. Automation emerges as the key to navigating these hurdles, offering a path to streamline operations.

Global trends further underscore the urgency of such solutions. Rural areas like Weißenburg often struggle with workforce scarcity, making manual labor-intensive processes unsustainable. Moreover, the push for greener operations aligns with consumer and regulatory demands, compelling companies to rethink energy consumption in logistics. DOTLUX’s automated facility addresses these issues head-on, setting a timely example for others.

Statistics paint a stark picture of the need for change. According to industry reports, over 60% of European manufacturers cite labor availability as a top constraint, while energy costs continue to climb. By adopting automation, DOTLUX not only tackles immediate operational bottlenecks but also positions itself to remain competitive in a market where agility and sustainability are non-negotiable.

Inside the Technology of DOTLUX’s Warehouse

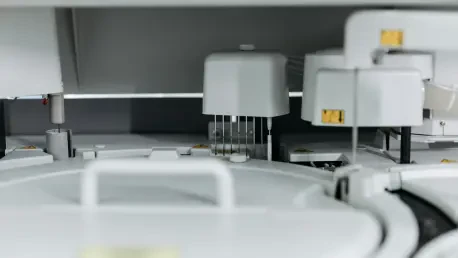

At the core of DOTLUX’s new facility lies the Movu atlas automated storage and retrieval system (ASRS), a marvel of modern intralogistics. Spanning 1,450 square meters, this setup boasts 2,900 pallet positions across four levels, managed by three shuttles and a single elevator. With a daily throughput capacity of 200 inbound and 150 outbound pallets, it eliminates manual handling through integrated conveyors.

This technology addresses multiple pain points with precision. Storage density is maximized within a compact footprint, reducing the need for expansive warehouse space. Safety is enhanced by minimizing forklift traffic, a common source of workplace accidents, while energy use per pallet is slashed, aligning with environmental goals. Such features place DOTLUX at the cutting edge of warehouse innovation.

Beyond raw numbers, the system’s integration with Movu OPS software ensures seamless coordination with DOTLUX’s existing IT infrastructure. This synergy allows for real-time data flow and operational stability, demonstrating how tailored automation can transform logistics from a liability into a strategic asset. The result is a facility designed not just for today, but for scalable growth in the years ahead.

Perspectives from the Innovators

Key figures behind this project offer valuable insights into its vision and execution. Matthias Schübel, COO at DOTLUX, emphasizes the strategic fit of the Movu atlas system, noting its ability to balance current operational needs with future expansion. “It’s about building a foundation that grows with us,” Schübel explains, highlighting the importance of adaptability in a dynamic industry.

Nico Kowarschik, Commercial Director at Movu Robotics, adds another layer of perspective, focusing on the power of turnkey solutions. “Automation isn’t just hardware; it’s a complete system that integrates effortlessly into a company’s workflow,” Kowarschik states. His comments reflect a broader industry shift toward holistic approaches that simplify the transition to advanced technologies for firms like DOTLUX.

These voices, combined with industry analysis, paint a picture of collaboration driving real impact. Experts note that automation adoption among mid-sized companies has surged by nearly 40% in recent years, as firms recognize the value of such partnerships. The Weißenburg project stands as a testament to how shared expertise can turn ambitious ideas into tangible progress.

Lessons for Businesses Embracing Automation

DOTLUX’s journey offers practical takeaways for companies eyeing similar transformations. A critical first step is identifying specific warehouse challenges, whether it’s limited space or staffing issues, and targeting scalable solutions like ASRS. Such systems can adapt to increasing demands without requiring constant overhauls, providing long-term value.

Collaboration with technology providers proves equally vital. Seamless integration of hardware and software, as demonstrated by the synergy between Movu OPS and DOTLUX’s systems, ensures smooth implementation. Businesses should seek partners who offer comprehensive support, minimizing disruptions during the shift to automated processes and maximizing operational uptime.

Finally, aligning automation with sustainability objectives can yield dual benefits. Energy-efficient designs, like those in the Weißenburg facility, reduce costs while shrinking environmental footprints. Companies of all sizes can draw inspiration from this approach, using technology to address both profitability and corporate responsibility in a competitive landscape.

Reflecting on a Milestone

Looking back, DOTLUX GmbH’s launch of an automated logistics facility in Weißenburg marked a pivotal moment for mid-sized manufacturers. The project, completed with the integration of the Movu atlas system, tackled pressing challenges of space, labor, and safety while embedding sustainability into its core. It stood as a beacon of what strategic foresight and technological adoption could achieve.

For businesses watching from the sidelines, the next steps were clear. Assessing internal logistics gaps and exploring automation options became imperative, with an eye toward scalable, energy-conscious solutions. Partnering with proven technology providers could ease the transition, turning operational weaknesses into strengths.

Beyond individual firms, the broader industry had much to consider. Weißenburg’s transformation hinted at a future where rural hubs could rival urban centers in innovation, provided the right investments were made. This project laid the groundwork for a dialogue on how automation could reshape manufacturing, urging stakeholders to think bigger and act sooner.