With decades of experience in management consulting, Marco Gaietti is a seasoned expert in Business Management, specializing in helping businesses navigate the complex worlds of strategic management and operations. Today, we’re diving deep into one of the most critical decisions for a scaling online business: choosing the right third-party logistics partner. Marco will share his insights on balancing warehouse strategy with tech, the importance of localized services for international expansion, how to choose between different fulfillment models, and the keys to a smooth technical integration and a transparent, fair contract.

Beyond just shipping costs, brands must weigh factors like strategically located warehouses against real-time inventory management. How should a growing business prioritize these features, and what specific metrics can you share for measuring a partner’s performance on both fronts?

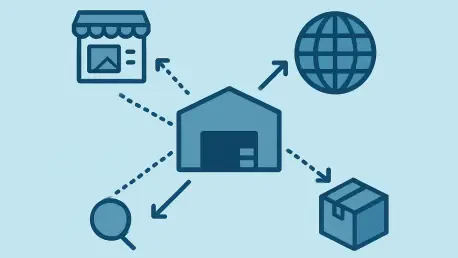

It’s a mistake to view these as competing priorities; they are two sides of the same coin, essential for a successful operation. You can’t have one without the other. Strategically located warehouses are your foundation—they directly impact the customer experience by enabling shorter delivery times and lowering your shipping costs. When evaluating this, look at a partner’s warehouse footprint, like the 16 facilities a provider like WAPI offers. The key metric here is simple: “time-in-transit.” Are you consistently hitting two-day shipping for your key customer regions? On the other hand, real-time inventory management is the nervous system. It’s the live visibility that prevents stockouts and allows for smart forecasting. You should be looking for a partner with a flexible tech layer that allows you to track live inventory, order status, and delivery performance. The crucial metric is inventory accuracy—is what the system says you have on the shelf matching the physical count with 99.9% accuracy?

For brands expanding into a market like Europe, some fulfillment partners offer specialized services like Cash-on-Delivery (COD). How crucial are such localized features for success, and what are the operational steps involved in managing COD and returns across multiple countries?

They are absolutely critical. I can’t stress this enough. Entering a new market without respecting local buyer preferences is a recipe for failure. In many parts of Europe, COD isn’t a “nice-to-have”; it’s a fundamental expectation that builds trust with consumers. Operationally, it’s a complex dance. First, your 3PL partner must have deep integrations with local carriers who are equipped to handle cash transactions upon delivery. Then, there’s the financial reconciliation process to get that cash back to you. The flip side is returns, or reverse logistics. With COD, you face a higher rate of refused deliveries, so your partner’s returns workflows must be incredibly efficient. The process involves receiving the returned item, inspecting it, and quickly putting it back into sellable stock to minimize losses, all while managing these movements across different countries and regulations. A partner that explicitly supports COD demonstrates a deep understanding of local-first fulfillment.

Some providers integrate fulfillment with end-to-end supply chains, while others cater to fast-moving DTC brands with variable demand. For a rapidly scaling company, could you explain the key trade-offs when choosing between these two models and provide an example of when one is clearly better?

The key trade-off here is between comprehensive control and nimble agility. A supply chain-led partner, like a Flexport, is designed for larger brands where fulfillment is just one piece of a massive global logistics puzzle that includes freight and multi-node distribution. Choosing them is about creating a predictable, centralized machine. The trade-off is that these systems can be less flexible for the sudden pivots a DTC brand might need. In contrast, a partner like NextSmartShip is built for the chaos of rapid ecommerce growth—handling campaign spikes and variable demand across multiple sales channels is their bread and butter. If you’re a fast-growing DTC brand that just landed a massive influencer collaboration and expects a 500% spike in orders next week, the agile, DTC-focused model is clearly the better choice. Their entire operation is geared toward that kind of elasticity, whereas the larger, supply-chain-focused model might struggle to adapt so quickly.

Seamless integration with major ecommerce platforms is a key requirement. What are the most common pitfalls you see during the onboarding process, and could you walk us through the essential steps a business should take to ensure a smooth transition to a new 3PL partner?

The most common pitfall I see is a lack of preparation and testing. Brands get so excited about the new partnership that they rush the technical setup. They connect their store, assume it works, and then get blindsided by order sync errors, incorrect inventory levels, or shipping notification failures right in the middle of a sales rush. It creates a terrible customer experience. A smooth onboarding process requires a methodical approach. First, you need a dedicated project manager on both sides. Second, you must conduct a thorough data audit—clean up your product SKUs, weights, and dimensions before you even think about migrating. The next essential step is sandbox testing. Run dozens of test orders through the system, covering every possible scenario: domestic, international, bundled products, returns. Only after you are completely satisfied with the test results should you go live, and even then, I recommend a phased rollout rather than flipping a switch overnight.

Transparent pricing and clear SLAs are crucial for a good partnership. What hidden costs should brands watch out for in a fulfillment contract, and what specific performance guarantees should be included in an SLA to ensure predictable delivery speeds and customer satisfaction?

Hidden costs are the bane of many a brand’s existence. The ones to watch for are often buried in the details: receiving fees for inbound shipments, long-term storage fees that escalate sharply, and “pick fees” that charge differently for the first item versus additional items in an order. Another big one is account management fees—make sure you know what level of support you’re paying for. As for the Service Level Agreement (SLA), it needs to be crystal clear and measurable. Don’t settle for vague promises. You need specific guarantees, such as “99.8% of orders received by 2 PM local time will be shipped the same day.” Other critical SLAs include inventory receiving time—how long from when your product arrives at the warehouse until it’s available for sale—and order accuracy rate. These guarantees are what transform a fulfillment provider from a simple shipper into a reliable partner that actively protects your customer satisfaction and brand reputation.

What is your forecast for the ecommerce fulfillment industry?

I believe the future of fulfillment is moving away from a one-size-fits-all model toward a more specialized and technologically integrated ecosystem. We’ll see less emphasis on just being the ‘cheapest shipper’ and far more on being a true operational partner. The winners in this space will be those who combine a wide physical footprint of strategically located warehouses with a highly flexible, AI-driven software layer that gives brands unprecedented visibility and control. Furthermore, as brands continue to expand globally, the ability to provide localized, culturally-aware services—like supporting specific payment methods or navigating complex customs—will become a non-negotiable differentiator, not just a feature. The industry is shifting from a B2B service to a B2B2C partnership, where the 3PL’s performance is directly and visibly tied to the end customer’s happiness.