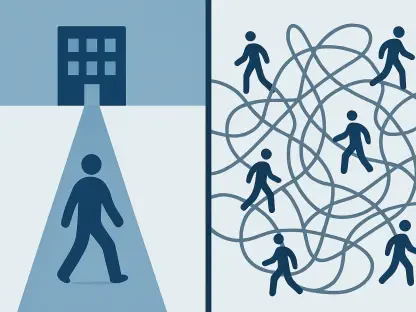

Winter in the logistics sector often paints a challenging picture, with warehouses battling snow, ice, and freezing temperatures that turn routine operations into potential hazard zones, disrupting workflows and impacting employee safety. A staggering statistic from industry reports reveals that slips and falls account for a significant portion of workplace injuries during colder months, especially during the busiest season. This roundup dives into the critical topic of preventing such accidents in warehouse environments, gathering insights, tips, and strategies from various industry sources and safety experts. The purpose is to provide a comprehensive look at winter hazards and actionable solutions, ensuring facilities remain safe and efficient even under harsh conditions.

Exploring Winter Challenges in Warehouse Settings

Winter weather introduces a host of risks to warehouse operations, from icy entryways to wet floors that heighten the chance of accidents. Industry professionals emphasize that snow and freezing temperatures can infiltrate through loading bays, creating slippery surfaces that endanger workers. The consensus among logistics managers is that these conditions demand heightened vigilance, especially during peak seasons when delays from injuries can cripple productivity.

Different perspectives exist on how to prioritize safety amidst operational demands. Some experts advocate for immediate, low-cost interventions like temporary barriers to block moisture, while others stress the importance of long-term structural adjustments to withstand brutal weather. This diversity in approach highlights the complexity of balancing cost with comprehensive protection, setting the stage for a deeper exploration of specific risks and tailored strategies.

The urgency to address these seasonal threats is universally acknowledged. Safety leaders note that small oversights, such as neglecting minor leaks, can snowball into major disruptions if not tackled early. This roundup compiles varied insights to uncover the most effective ways to navigate these challenges, ensuring warehouses remain secure for staff and goods alike.

Key Winter Risks and Proven Safety Measures

Weatherproofing Entry Points to Stop Moisture

Entryways and loading docks often bear the brunt of winter’s wrath, with snow and water seeping in to create dangerous, slick surfaces. Many industry voices point out that this moisture not only poses a slip risk but can also damage inventory if unchecked. A common recommendation is the use of absorbent barriers or temporary seals, which several logistics firms have found effective in curbing water intrusion without hindering access.

Contrasting views emerge on the investment required for such measures. While some safety consultants suggest that low-budget solutions can suffice for smaller facilities, others argue that larger warehouses need robust, permanent fixes to handle high traffic and severe weather. The debate often centers on weighing initial costs against the potential expense of damaged goods or employee injuries, with most agreeing that prevention trumps reaction.

Practical tips from seasoned managers include regular inspections of door seals and installing weather-resistant curtains. These steps, though simple, have been praised for their ability to maintain a dry, safe environment. The collective advice underscores that protecting entry points is a foundational step in a broader winter safety plan, tailored to the unique needs of each facility.

Boosting Floor Safety to Reduce Slip Hazards

Wet or gritty floors rank high among winter safety concerns, particularly in high-traffic warehouse zones where accidents frequently occur. Data shared by safety organizations indicates that a notable percentage of annual workplace injuries in logistics stem from slips, especially during colder months. Experts widely recommend grippy mats and anti-slip coatings as immediate solutions to enhance traction and minimize risks.

Opinions vary on the best approach to floor safety, with some advocating for quick, affordable fixes like temporary mats, while others push for durable, long-term coatings despite higher upfront costs. The latter group often highlights how such investments boost worker confidence and reduce downtime, creating a safer, more productive environment over time.

Additional insights focus on the importance of routine cleaning to remove debris and moisture. Several warehouse supervisors have noted that combining regular maintenance with safety upgrades offers the best defense against slips. This multi-layered strategy reflects a growing recognition that floor safety is not a one-time fix but an ongoing commitment to employee well-being.

Preparing for Spills and Leaks in Freezing Weather

Freezing temperatures heighten the risk of pipe bursts and machinery leaks, turning minor issues into significant hazards if not addressed swiftly. Industry feedback reveals that such incidents can halt operations, especially in logistics hubs where timing is critical. A shared tip among safety professionals is to keep well-stocked spill kits readily available and train staff for rapid response to contain messes before they spread.

Differing perspectives arise on the level of preparation needed, with some experts suggesting that proactive equipment checks are essential to prevent leaks, while others caution against underestimating the impact of cold on aging infrastructure. Real-world examples from distribution centers show that facilities with regular maintenance schedules often avoid costly disruptions, reinforcing the value of foresight.

The conversation also touches on the scalability of spill readiness. Smaller warehouses may manage with basic kits, but larger operations might require advanced systems and dedicated response teams. This range of advice illustrates the need for customized plans, ensuring that spill management aligns with the specific risks and resources of each facility.

Preventing Flooding with Drainage Maintenance

Clogged or neglected drainage systems pose a hidden threat during winter, with the potential for flooding affecting a measurable percentage of transport and storage firms, according to recent industry data. Safety advocates stress that blocked drains can lead to standing water, creating slip hazards and damaging equipment. Routine inspections and cleaning are frequently cited as vital defenses against this often-overlooked issue.

Regional differences in flood risk due to varying winter climates spark diverse opinions on prioritization. Facilities in areas with heavy snowfall may need more aggressive maintenance schedules, while milder regions might focus on periodic checks. Experts generally agree, however, that assuming flooding is a rare event is a dangerous oversight, urging managers to integrate drainage vigilance into standard protocols.

Practical guidance includes documenting drainage conditions and addressing issues before storms hit. Several logistics leaders have shared success stories of averting floods through preemptive action, highlighting how such diligence saves time and resources. This collective wisdom challenges complacency, positioning drainage care as a critical component of winter safety planning.

Crafting a Strong Winter Safety Plan

Drawing from the array of insights, a robust winter safety framework emerges as essential for logistics operations. Key takeaways include sealing entry points to block moisture, enhancing floor safety with traction aids, preparing for spills with accessible kits, and maintaining clear drainage systems to prevent flooding. These interconnected steps, endorsed by various industry sources, work together to reduce accidents and keep operations running smoothly.

Actionable advice for warehouse managers includes investing in affordable safety tools like mats and barriers while scheduling consistent maintenance checks. Embedding winter preparedness into daily routines, rather than treating it as a seasonal afterthought, is a recurring theme among safety professionals. This approach ensures that both minor and major hazards are addressed before they escalate.

Further recommendations involve fostering a culture of safety through staff training and regular hazard assessments. Differing views on implementation timelines exist, with some suggesting immediate action and others favoring gradual integration, but the shared goal is clear: protecting workers and minimizing downtime. These compiled strategies offer a practical roadmap for fortifying warehouses against winter challenges.

Reflecting on Winter Safety Insights

Looking back on the diverse perspectives gathered, it is evident that proactive measures form the cornerstone of winter safety in warehouses. The varied tips—from weatherproofing entryways to maintaining drainage—highlight a unified commitment to reducing slips and falls. Each expert and industry source contributed unique angles, yet all converged on the importance of preparation over reaction.

Moving forward, logistics leaders are encouraged to assess their facilities for vulnerabilities and implement at least one safety upgrade, such as installing anti-slip mats or conducting a drainage audit. Exploring emerging safety technologies, like automated hazard detection systems, also stands out as a promising avenue for enhancing protection. These next steps aim to build on the foundation laid by current practices.

Additionally, staying informed about regional weather patterns and adapting plans accordingly emerges as a vital consideration. Collaborating with safety organizations for updated guidelines could further strengthen preparedness. These actionable insights, drawn from the roundup, pave the way for safer, more resilient warehouse operations in future winters.