The transformative role of digital twin technology in modern business environments cannot be overstated; it enhances product development processes, making businesses more competitive and adaptive to changes. Digital twins, which are virtual replicas of physical products, are increasingly adopted across various industries due to their ability to simulate real-world scenarios and provide detailed insights into product behavior and performance.

Benefits of Digital Twins

Industries such as automotive, aerospace, and defense have been leading the charge in utilizing digital twins, while sectors like logistics, infrastructure, and energy are on the cusp of major adoption. One evident advantage of digital twins is that they allow for extensive exploration of design options in a risk-free environment, circumventing the high costs associated with physical prototypes. Real-world scenario simulations offer enhanced testing and validation, enabling thorough assessments of new solutions. Additionally, digital twins facilitate detailed product insights, allowing better monitoring and understanding of complex product interactions and behaviors. Data-driven improvements become much more feasible as real-world data can inform and optimize product designs and updates.

McKinsey Study Insights

A McKinsey study underscored the significant impact of digital twins on product development, highlighting reductions in development times by 20-50%, lower prototype costs, and minimized problems. Moreover, this technology also increases the likelihood of commercial success and ushers in value-added services like predictive maintenance.

Addressing Development Challenges

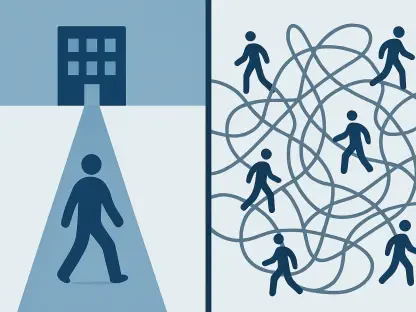

Modern product development faces challenges such as managing complex and heterogeneous data, adapting to diverse market requirements, and the necessity of better collaborative tools. Digital twins address these issues by integrating various data types into a cohesive system, enhancing cross-functional collaboration, and providing comprehensive insights into product performance and needs.

Use Cases Across Industries

In the realm of consumer electronics, digital twins can improve supply chain quality and resilience by optimizing production processes and reducing waste. In the automotive industry, digital twins facilitate global collaboration in 3D design, avoiding delays typical in standard rendering software. For industrial manufacturing, these virtual replicas trace products from conception to use, identifying quality problems early and reducing failure risks. In aerospace, digital twins simulate and optimize aircraft components and systems, cutting down on testing and certification time and costs. The energy sector benefits from digital twins by optimizing power plant and infrastructure performance through simulations of various operational scenarios.

Adoption Process

Adopting digital twins involves a phased approach that addresses technological challenges, architectural designs, integration issues, and organizational transformation. Having a skilled partner is crucial for successful implementation, and senior management’s support is imperative for this transformative effort to be effective.

Conclusion

The transformative impact of digital twin technology on modern business environments cannot be emphasized enough. This innovative technology significantly improves product development processes, making companies more competitive and adaptable to changes. Digital twins are virtual models of physical products. By creating these digital replicas, businesses can simulate real-world scenarios, gaining in-depth insights into how products will behave and perform over time.

As industries increasingly adopt digital twin technology, it’s evident why these tools are becoming indispensable. They enable businesses to predict and rectify potential problems before they arise in the physical world. This predictive capability can save both time and resources, leading to more efficient and cost-effective operations.

Moreover, digital twins facilitate real-time monitoring and data analysis, assisting companies in making informed decisions quickly. This leads to streamlined operations and the ability to respond dynamically to market demands and environmental changes. In short, digital twin technology is a game-changer that drives growth and innovation in today’s fast-paced, technology-driven marketplace.