What if the vehicle you drive daily could significantly cut down on environmental harm, built from parts that have already lived a life on the road, and crafted with a vision for a greener future? This concept is not a distant dream but a tangible reality being shaped by a Swedish automaker known for safety and, now, sustainability. Volvo Cars is spearheading an eco-revolution in the automotive world, crafting vehicles with recycled materials and setting ambitious benchmarks for a greener future. This journey toward sustainability isn’t just about reducing waste; it’s about redefining how cars are made and perceived in an industry often under scrutiny for its ecological impact.

The importance of this shift cannot be overstated. With global climate concerns mounting and consumer demand for sustainable products rising, automakers face immense pressure to adapt or risk obsolescence. Volvo’s commitment to integrating recycled content and achieving carbon neutrality stands as a beacon of innovation, challenging larger competitors to follow suit. This story delves into how a company with fewer than 800,000 vehicles delivered annually is making outsized strides in an industry giant’s playground, proving that size does not dictate impact when it comes to environmental responsibility.

Why Sustainability in Cars Matters

The automotive sector contributes significantly to global emissions, accounting for roughly 15% of total greenhouse gas output worldwide, according to recent studies. This staggering statistic highlights the urgent need for change in how vehicles are produced and powered. Consumers are increasingly aware of their carbon footprint, pushing for options that align with eco-conscious values while governments tighten regulations to curb pollution. Volvo’s focus on recycled car production addresses these concerns head-on, offering a glimpse into a future where driving doesn’t come at the planet’s expense.

Beyond emissions, the sheer volume of waste generated by car manufacturing poses another critical challenge. Millions of tons of materials end up in landfills each year as vehicles reach the end of their lifecycle. By prioritizing recycled components, Volvo tackles this issue directly, reducing the demand for virgin resources and minimizing waste. This approach not only conserves natural resources but also sets a precedent for what responsible production looks like in a resource-scarce world.

The Wider Lens: Environmental Trends in Automotive

Across the globe, the push for sustainability is reshaping the automotive landscape, driven by both consumer expectations and stringent policies. In Europe, the EU’s mandate for all new vehicles to be electric by 2035 exemplifies the aggressive timelines set for change, while Asia, particularly China, leads as the largest electric vehicle market. Meanwhile, the U.S. grapples with fluctuating policies that sometimes hinder a rapid transition to greener technologies. Volvo navigates this complex terrain by aligning with progressive standards, positioning itself as a key player in the shift toward circular economies.

This broader movement isn’t just about electrification but also about rethinking the entire lifecycle of a vehicle. Circular economy principles, which emphasize reuse and recycling, are gaining traction as a way to reduce environmental degradation. Volvo’s efforts to incorporate these ideas into its core operations reflect an understanding that sustainability is a multifaceted challenge requiring innovative solutions across production, usage, and disposal stages. This holistic perspective distinguishes the company in a competitive field still grappling with balancing profit and planet.

Volvo’s Strategy for Recycled Vehicle Manufacturing

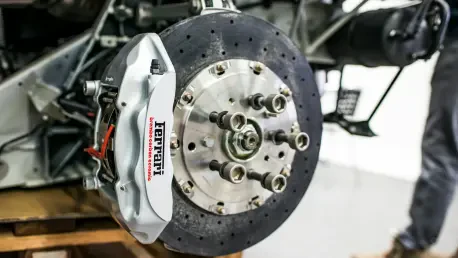

At the heart of Volvo’s transformation lies a detailed plan to revolutionize car production through recycled materials. The company aims for 35% of content in new vehicles to be recycled by 2030, with a long-term vision of full circularity by 2040. The ES90 premium electric vehicle showcases early success, boasting 29% recycled aluminum, 18% recycled steel, and 16% recycled polymers. These figures highlight tangible progress, though hurdles remain in scaling such achievements across all models.

Manufacturing processes are also undergoing a sustainable overhaul. Since transitioning to carbon-neutral energy sources like biogas in key plants in Sweden and China starting from 2025, Volvo continues to innovate with techniques like megacasting—using a single large aluminum part instead of multiple smaller ones to cut emissions. A new facility in Slovakia, operational this year, adheres to these eco-standards, while water usage reduction targets of 50% across operations underscore a commitment to broader environmental stewardship.

Electrification remains a cornerstone, with plans for an all-electric lineup aligning with EU targets, though strategic adjustments like plug-in hybrids cater to the U.S. market’s slower policy shifts. Battery production, however, presents persistent challenges, with limited lithium supplies and carbon-intensive processes tied to global supply chains complicating recycling efforts. Despite these obstacles, Volvo’s roadmap illustrates a determination to overcome barriers through persistent innovation and adaptation.

Expert Perspectives on Volvo’s Sustainability Push

Insights from Volvo’s leadership provide a window into the company’s ambitious vision. Chief Sustainability Officer Vanessa Butani, a recognized figure in sustainability circles, emphasizes transparency as a core value, pointing to initiatives like battery passports—rolled out ahead of EU mandates. These digital records detail the origin and production impact of battery materials, empowering consumers with knowledge about their vehicle’s environmental footprint and reinforcing trust in the brand’s eco-claims.

Industry experts also weigh in, noting that Volvo’s smaller scale offers a unique advantage over larger automakers bogged down by legacy systems. This agility allows for quicker adoption of cutting-edge practices, setting benchmarks that pressure giants to accelerate their own green transitions. However, analysts caution that recycling complexities, especially for electronics and lithium-ion batteries, require industry-wide collaboration to solve, suggesting Volvo’s leadership could catalyze broader change if paired with collective action.

Lessons from Volvo: Driving Change Across the Board

Volvo’s journey offers valuable lessons for various stakeholders looking to contribute to a sustainable automotive future. For consumers, understanding tools like battery passports can guide informed purchasing decisions, prioritizing vehicles with lower environmental impacts. This transparency empowers buyers to support brands that align with their values, amplifying market demand for eco-friendly options.

Policymakers can draw inspiration from Volvo’s alignment with strict EU regulations, advocating for incentives that promote recycled materials and electric vehicle adoption. Such policies could accelerate industry-wide shifts, creating a supportive framework for innovation. Meanwhile, other automakers might consider adopting practices like megacasting or setting bold recycled content targets to remain competitive in a rapidly evolving market, learning from Volvo’s proactive stance to stay ahead of regulatory and consumer expectations.

Reflecting on Volvo’s strides, it becomes evident that impactful change often stems from bold, calculated risks taken in the face of industry norms. The commitment to recycled materials and carbon-neutral operations challenges conventional production methods, proving that sustainability and profitability can coexist. As the automotive sector moves forward, Volvo’s legacy stands as a reminder that smaller players can drive monumental shifts, inspiring a reevaluation of what is possible. Looking ahead, the focus must shift to collaborative innovation—especially in battery recycling—to address remaining gaps, ensuring that the road to a greener future is paved with shared solutions and sustained momentum.